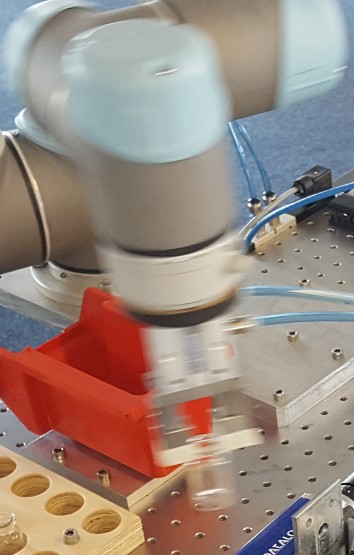

Machine Vision for Tablet Dispensers Inspection

Fully automated inspection of tablets and dispensers

A fully automated machine vision system for the inspection of packed tablets. The vision system inspects tablet dispensers to detect wrong-colored tablets, broken or missing tablets, and missing or defective covers on the dispenser.

Tablets are fed into the dispenser and packaged automatically. In the last operation, the transparent lid is mounted. When the finished dispenser leaves the machine three color cameras inspect the dispensers.

Each tablet is located and the color is determined. The tablet position in the grove is measured and thereby turned-over or broken tablets are found. Debris from broken tablets in the dispenser is found. The last inspection checks the position of the plastic lid and finds cracks and other damage in the transparent surface.

The tablet inspection is dynamic and tolerates the natural variation in the tablet color without making false rejects. A large diversity of color tables can be inspected. When new a variant is introduced, the system will check 30 fault-free dispensers and calculate the color data. The system rejects defective dispensers and collects statistical data.

Why choose the JLI Tablet Dispensers Inspection System?

- Color inspection

- A wide variety of tablet types can be integrated

- Production report generated at batch level

- Integrated into the packaging machine

- Compact design

- Automatic operation – no operator input is needed

- Easy setup for new dispenser models

- Internet connectivity for easy support

- Comprehensive production data

Example systems in

Medical Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)