Machine Vision for Prefilled Syringes Inspection

Automated inspection of a time-consuming and difficult task

The risk of contamination of the drug inside makes cracks in syringes a critical fault in any injection system. The barrier for this fault is often a time-consuming manual inspection of all syringes that leaves the manufacturer with high expenses and very little certainty that all cracks have been found.

The JLI Prefilled Syringes Crack Inspection System enables the detection of small chips and cracks in pre-filled syringes with full coverage of the syringe including areas such as plunger, plunger rod, labels, and liquids. The system replaces a time-consuming and often error-prone manual control.

The system is an automatic 100% (online) inspection machine that maintains a very high and uniform detection level on both naked and labeled syringes. Cracks down to 1mm in length will be detected in the liquid-filled part of the syringe as well as in the area with the plunger and the plunger rod.

20 years of experience in glass inspection has been combined with experience in label inspection to design a system that will find cracks in between the letters of a printed label at up to 120 parts per minute.

The system can be integrated into both indexed and continuous motion machinery or it can operate as a complete stand-alone inspection station.

.jpg?width=325&height=216&name=prefilled-syringes%20(1).jpg)

Why choose the JLI Prefilled Syringes Inspection System?

- Installed online for 100% inspection

- Developed according to GAMP5 and 21CFR PART 11

- Calculates statistical data and displays trend information

- Innovative lighting techniques

- Inspects both naked and labeled syringes

- Up to 120 parts per minute

- Cracks down to 1mm in length can be detected

Example systems in

Medical Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

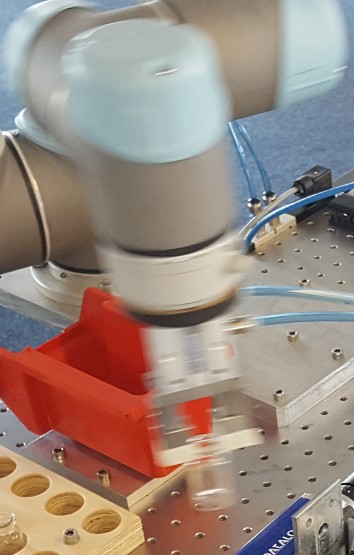

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)