Machine vision for Moulded Parts Inspection

A tailored solution for inspecting dimensions and surfaces

The production of medical devices is a critical manufacturing process. Making faulty components can cause bodily harm or even death. Precise inspection and accurate records are essential and demanded by the Food and Drug Administration.

As the moulding processes mature we see more and more critical components manufactured using moulds. This ensures a highly automated process, but components still have to be inspected to document the product quality or adjust the moulding process itself.

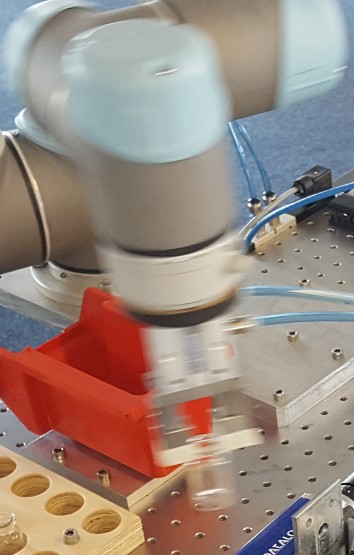

The JLI vision Moulded Parts Inspection System is a fully automated 100% inspection system that can be tailored to measure the dimensions and surface qualities that are critical for a specific product. A broad range of dimensional measurements are available and special requests are easily implemented - even if they require complex part movement to be measured correctly.

Everything from lighting to calibration is handled by vision experts and the system is delivered as a turnkey, validated package with a functional guarantee.

Why choose the JLI Moulded Parts Inspection system?

- Dimensional accuracy < 1 micron

- Surface / visual errors are detected with minimal contrast deviations

- Calculates statistical data and displays trend information

- Preventive maintenance

- 100% inspection

- High-accuracy dimensional measurements

- Surface quality control

Example systems in

Medical Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)