Machine Vision for Needle Inspection

Extremely precise inspection of needles for defects

A system for precision measurements of details on needles. The system inspects a macro area of the needle tip and detects dimensional errors and the surface of the needlepoint after grinding. Precision is better than one micron.

Manual inspection of needles is labor intensive and not uniform in the long term. The JLI Needle Inspection System eliminates all manual inspection and ensures high quality in the production of advanced needles.

The inspection system can be integrated into the production environment and will inspect any needle for dimensional errors, burrs, hooks, and even exopy cavities. Any drifts in the grinding of the needle tip can be detected in real-time and communicated to operators or production equipment.

When the quality of a needle exceeds preset tolerances a reject/accept signal is controlled. This will increase the effectiveness of the production. The needle inspection system can interface with any production database for statistical process control purposes.

Why choose the JLI Needle Inspection system?

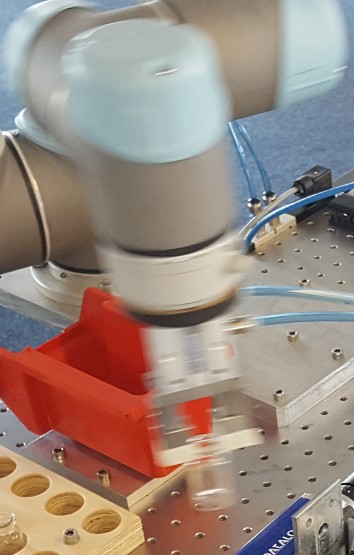

- Can be integrated with automatic handling equipment

- Detects burrs from multiple angles

- Single camera system

- Elaborate dimensional measurements

- Burr detection

- Hook detection

- Epoxy cavity inspection

- 2 micron accuracy

- 24 hrs online data collection

Example systems in

Medical Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)