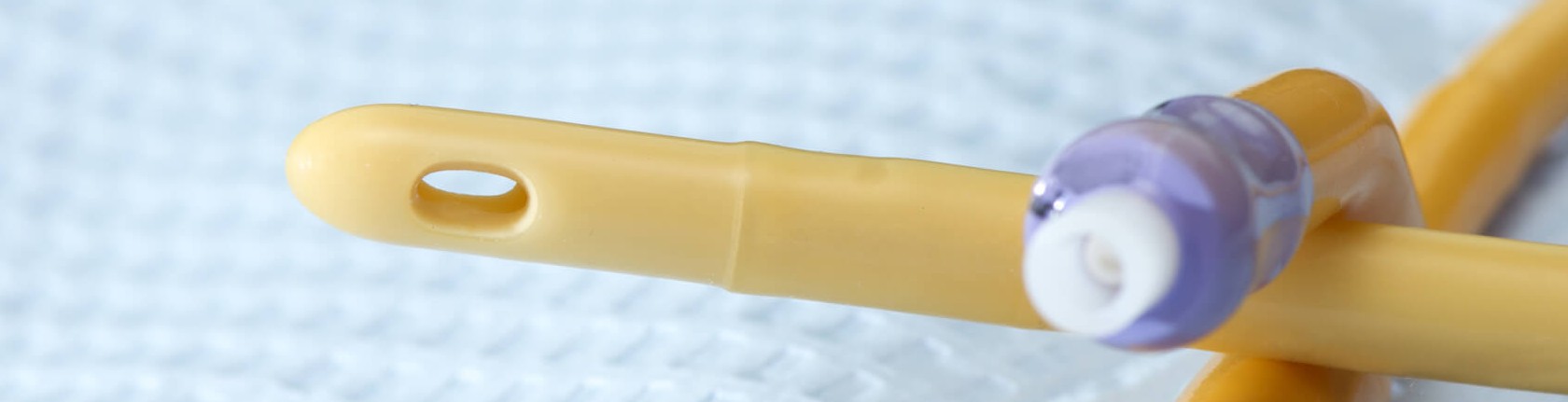

Machine Vision for Catheter Inspection

Catheter inspection to high pharmaceutical standards

Catheter inspection can be integrated into existing production machinery. Special optics make it possible to inspect 360 degrees with only a 120-degree rotation.

JLI’s pharmaceutical catheter inspection system is a compact unit that can be installed inline. The system is now second generation and has been developed to meet the high demands of the pharmaceutical industry with regard to quality and validation. The system can be used for a wide range of different catheters such as urethral and intravenous production.

The inspection system employs three high-resolution matrix cameras and customized stabilized long-life light sources.

Catheters are inspected for tip, punch holes, and tube errors. Through the user interface, the sensitivity can be set and defect patterns can be selected. This is easily done through a touch panel.

When defects exceed a selected tolerance, a signal is timed and can be sent to a reject mechanism. On request, the system can create production reports.

Why choose the JLI Catheter Inspection System?

- Typical inspections include: tip, eyes and surface impurities

- Systems are available for inspection of coated catheters

- Batch controlled

- Production report for documentation purposes

- High accuracy tip and punch hole analysis

- 21 CFR PART 11 compliant

- Installed online on manufacturing equipment

Example systems in

Medical Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)