Machine Vision for Steel Inspection

Steel Inspection

Quality control in steelworks is a challenging discipline for several reasons. The high temperature means that manual inspection is impossible or at least inappropriate and it places high demands on both the hardware and design of an automated inspection solution.

JLI vision has extensive experience developing customized vision systems for steel inspection - from dimensional measurements on red-hot slabs to the detection of critical surface defects on steel elements.

All equipment is designed for the relevant environment. This can include water-cooled and air-blown camera housings suitable for operation at temperatures exceeding 2000C.

The JLI Steelworks Inspection Systems are custom-designed turnkey solutions for measuring dimensions, shapes, surface defects, and flatness in both the hot and cold end.

Why choose a JLI turnkey Steel Inspection System?

Custom-made and adapted to existing production lines

Steelworks are typically challenging production environments where standard solutions come up short.

A robust solution for harsh environments

Designed to last in harsh environments with high temperatures and still detect even the most challenging defects with the same high level of accuracy every time.

Improved profitability

By reducing the ongoing costs of manual inspection, reducing waste, and improving quality you will improve your profitability.

---> Download our steel inspection brochure

Extensive experience with steel inspection

JLI has developed advanced machine vision solutions for steel inspection since 1987. We have many installations, some still in service after more than 20 years.

In this video, Vision Engineer Frederik Thiesson shows you how we overcome the challenges of high temperatures on a production line.

Steel inspection case study:

JLI has developed a machine learning solution for anomaly detection on top of an inspection system for rails.

The detection accuracy is >95% which is better and more consistent than the previous manual inspection.

Examples of steel inspection systems

Our steel inspection systems cover a broad range of applications.

- Alpha Numeric Readers on hot and cold steel

- Dimensional measurements

- Position

- Shape identification

- Volume and weight

- Surface inspection of sections

- Product lengths on cooling bed, Rebar and Rails

Alphanumeric readers are used to track products and ensure that the right steel is processed and delivered to the right customer.

Dimensional measurements are done on hot and cold products. The accuracy can be impressive and exceed the standard methods.

Optimizing titanium discard

One of the first steel inspection systems was for Bloom cropping Inspection. The system measured the position of git end or fishtail at bloom cropping. The measurements were used to optimize the discard calculated from bloom length. As the mill produces titanium steel the saving when discarding correctly meant a payback time of 14 days.

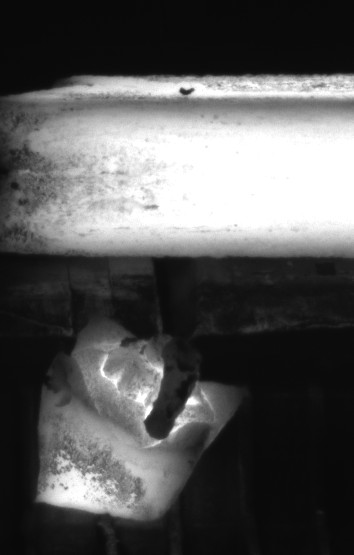

Checking dimensions on red-hot slabs

Machine Vision for Slab Gauge Inspection, measures the slabs accurately just before rolling. This ensures that it is the right slab for the rolling program. A wrong (too thick) slab can cause expensive damage to the mill. These systems are normally mounted on the lighting walkway or on the roof where they are well away from the hot steel.

Automating labor-intensive processes

Rails are now produced in lengths over 100 meters. To inspect the rail surface the operator walks up and down the entire length. This means walking a distance of more than 10 miles on an 8-hour shift. The need for automation was obvious.

The rail surface inspection system uses 6 cameras mounted on a ring with flood lights. This gives full coverage of rails and beams.

The first system was installed in 2009, and we have developed machine learning algorithms to fully automate fault detection.

Machine Vision for Steel Inspection

.png?width=288&height=288&name=Mockup%20steel%20Brochure_no%20background%20(1).png)

The brochure will tell you how vision systems can be used for inspection of products in the steel industry.

The brochure will go through how you can optimize your QC process by:

- Streamlining the inspection process

- Detecting defects

- Improving quality control

- Automating the inspection process

Fill in the form, and get your Steel Inspection brochure. At the same time you submit to our Newsletter which will provide you with relevant information, news, and offers that refer to the world of machine vision.

Example systems in

Glass Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting