Machine Vision for Slab Concast Inspection

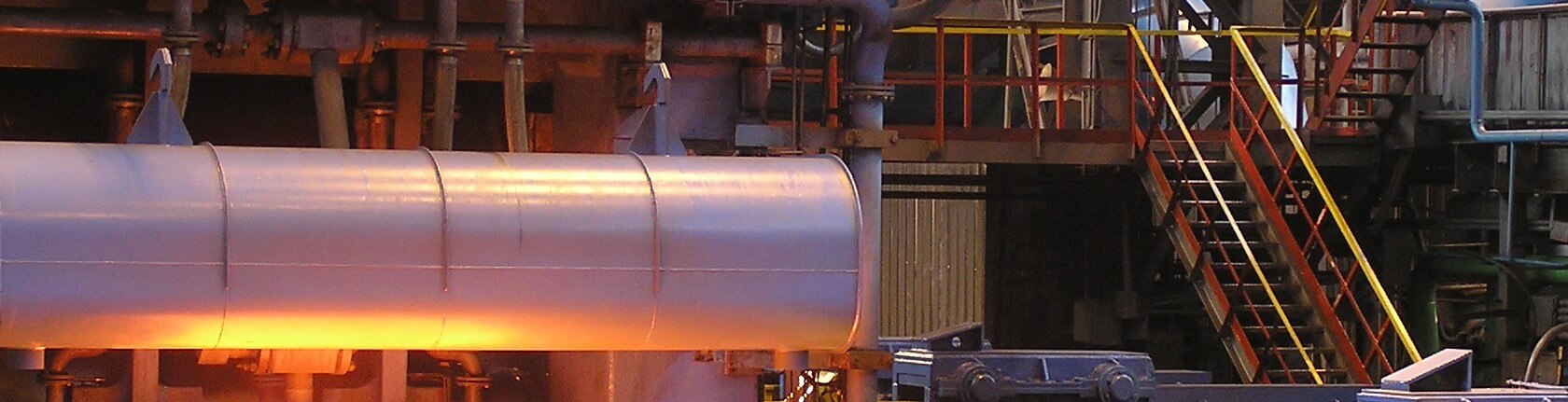

Exact measurement of red-hot steel slabs

The speed and dimensions of concast steel are typically measured mechanically. The JLI Slab Concast Inspection System eliminates the contact wheel and manual measurement procedures. The accuracy is 0.1% on speed, 0.5 mm on thickness, and 2 mm on width. This data and information enable the steelworks to cut slabs to an exact weight.

Instrumentation for the concast plants presents tough environmental challenges. The JLI vision system utilizes water-cooled camera housings with air-purged heat-reflecting front glass.

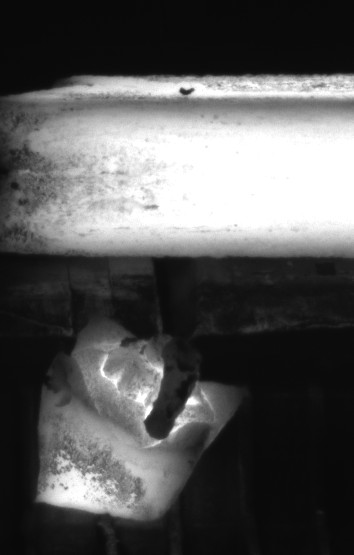

The system measures the thickness, width, and speed of the red-hot steel. Three cameras are used for each strand. One camera is mounted at the side looking directly at the surface of the slab to gauge thickness. Two cameras are mounted at the side looking down at a steep angle to measure the width at the bottom of the slab.

The camera looking at the side records the pattern of the scale and follows this through the image. Thereby the casting speed is measured. Knowing the density, the measurements of volume are converted to weight. When a pre-programmed amount of steel has passed the cameras, a signal is given to clamp the torches to cut slabs at the exact weight.

Why choose the JLI Slab Concast Inspection system?

- Non-contact measurement in the harsh concast environment

- Interface to Mill computer

- Clamp signal based on weight calculations

- Accuracy: 100 kg on a 20 tonne slab, all included

- Ruggedized unit for concast environment

- Special installation and cables

- Timed clamping signal for the torches

- Easy-to-use interface and displays with trend graphs

- Internet connectivity for easy support

Example systems in

Steel Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)