Machine Vision for Slab Gauge Inspection

Precise meaurement of slab dimensions

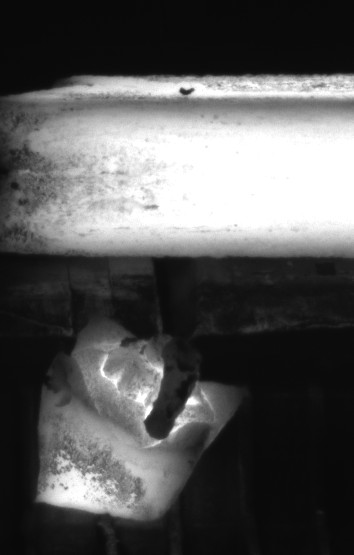

The slab dimension systems are typically installed before the primary mill. At this location, the system can be used to check the slab size before the first pass.

Slabs need to be measured at several points in the process. Just before rolling it is vital to ensure that it is the right dimension slab that is ready for rolling. If it is the wrong size the result will be a plate rolled to wrong dimensions, or even worse it could wreck the mill stand.

The vision system camera is mounted 20 meters above the transfer table at the lighting walkway. When the slab passes under the optical center of the camera, a series of length and width measurements are calculated and averaged.

A 12 meter long slab will be measured with accuracy better than 12 mm.

The system is fully automatic and triggers when the slab is passing under the camera. The measurements are passed to the mill computer and to the mill operator.

Why choose the JLI Slab Gauge Inspection System?

- Single camera operation

- Camera installation away from the hot environment

- Software to prevent false measurements due to steam

- Fast continuous operation

- Displays tailored for pulpit requirements

- Remote control

- Stand-alone unit

- Triggers automatically

- Maintenance free

- Internet connectivity for remote servicing

- Accuracy better than 0.1% of the slab length

- Measures red-hot slab

Example systems in

Steel Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)