Machine vision for Bar Length Gauge Inspection

Length measurement in rugged conditions

When rolling long products it is beneficial to measure the total length of each bar. Several schemes are employed at steelworks today, but vision technology presents a clean and easy solution.

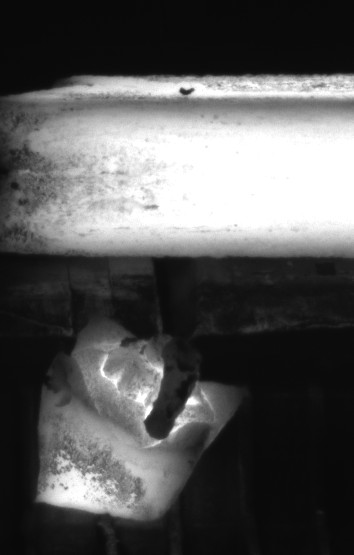

The cameras are placed above the cooling bed on the outside of the roof. The system detects when the bar is moved from the roller lane to the walking beams. Reference marks are used for calibration in every measurement cycle.

The vision system will in principle provide an array of “photocells” over the cooling bed. The benefit is that the photocells – “pixels” are behind a lens at a good distance from the red-hot steel. Each pixel has a known and calibrated location on the roller table and the vision programs will then access these individual points as decided by the program.

Using cameras mounted under the ceiling will give a ruggedized installation away from heat and crane movements. When the bar enters the cooling bed the cameras identify this and switch from camera to camera to find the nose and tail.

The exact coordinates in relation to fix points at the cooling bed are then determined and the total length is calculated with an accuracy of 10 mm. The number of cameras used depends on the maximum length of the runout, and the ceiling height.

Why choose the JLI Bar Length Gauge Inspection System?

- Self calibrating

- Easy access to the cameras also during production

- Accuracy on a 100 m bar is 25 mm

- Stand alone unit

- Triggers automatically

- Maintenance free

- Internet connectivity for remote servicing

- Interface to mill computers

- Measures red hot slabs

Example systems in

Steel Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)