.png?width=1680&height=431&name=Tube%20End%20Inspection.1png(1).png)

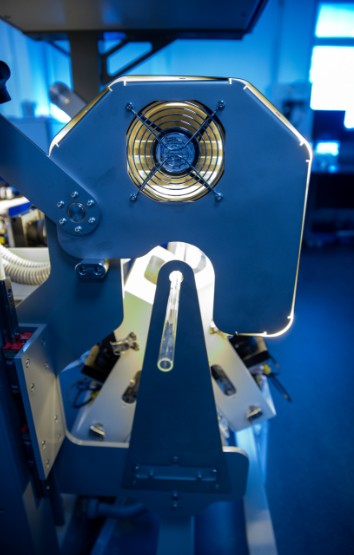

Machine Vision for Tube End Inspection

High-precision inspection of glass tubes

JLI vision’s latest generation tube end inspection system satisfies the demand for high-precision inspection which is required in e.g. the solar industry.

By looking at the glass tubes from the ends after cutting, outside and inside diameter, wall thickness, out-of-round, siding, and ovality can be measured with accuracies down to 5 microns. In addition chips, cracks, end-shape glazing thickness, tube length, and bow can be measured by applying more cameras. Hereby defective and off-spec tubes can be rejected before packing.

As an add-on, the system can be equipped with cameras for measuring shoulder dimensions on end-formed tubes.

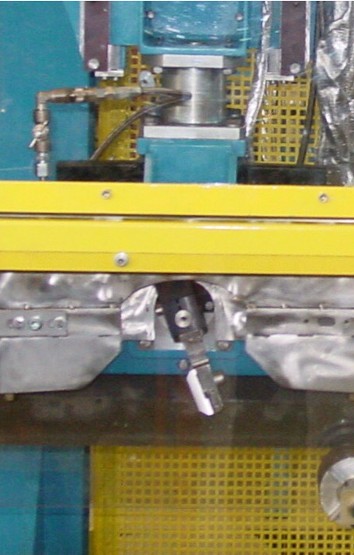

The system is modular and can be mounted on existing conveyors. Because measurements are done in-line in sync with the conveyor movement, tube handling is very limited and the only modification to the conveyor is to add a “star wheel” or a similar mechanism. A reject device is connected to the system, and statistical information will be available for process control equipment, etc.

By looking at the glass tubes from the ends after cutting, outside and inside diameter, wall thickness, out-of-round, siding, and ovality can be measured with accuracies down to 5 microns. In addition chips, cracks, end-shape glazing thickness, tube length, and bow can be measured by applying more cameras. Hereby defective and off-spec tubes can be rejected before packing.

Why choose the JLI Tube End Inspection System?

- High accuracy down to 5 microns

- Diameters 10-70 mm

- Capacity up to 5 tubes/s

- Measures OD, ID, WT, out-of-round and siding

- Detects chips, cracks and end shape irregularities

- Measures fuse dimension, tube length and bow

Example systems in

Glass Inspection:

Designed and developed to meet high demands for speed and sensitivity.

Reduce waste by up to 40%

The system will continuously measure and inspect tableware as the glasses pass on a conveyor.

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)