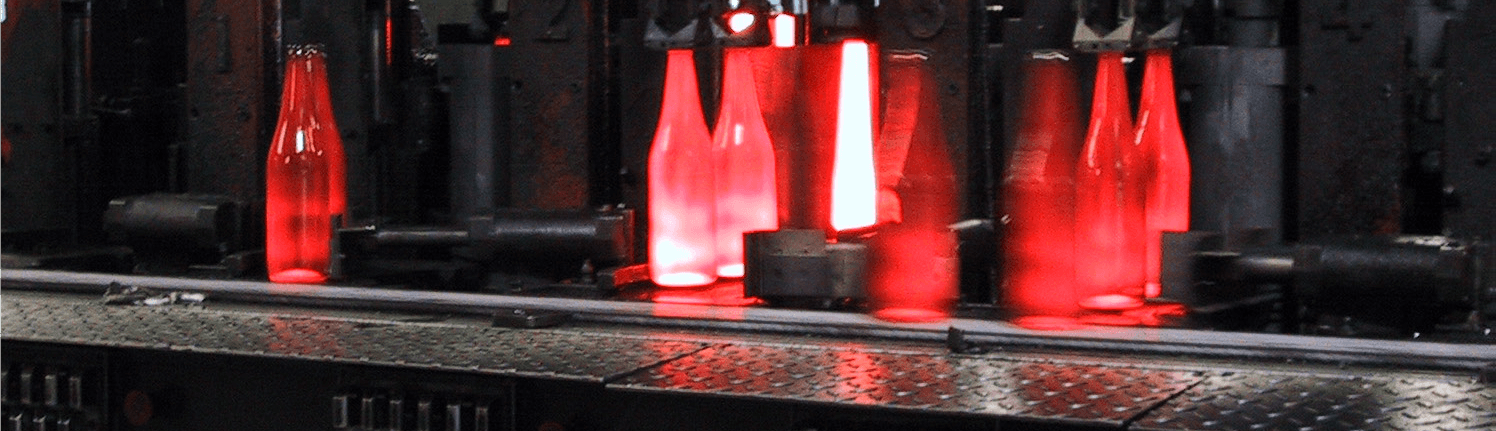

Machine Vision for Hot End Container Inspection

Analyze trends and find defects at the time of production

A process management tool designed to aid operators and process control personnel in managing the quality of containers at the time of production.

Process trends as well as quality-related and critical defects can be identified as containers are produced, providing immediate feedback to machine operators. Defect detection and classification.

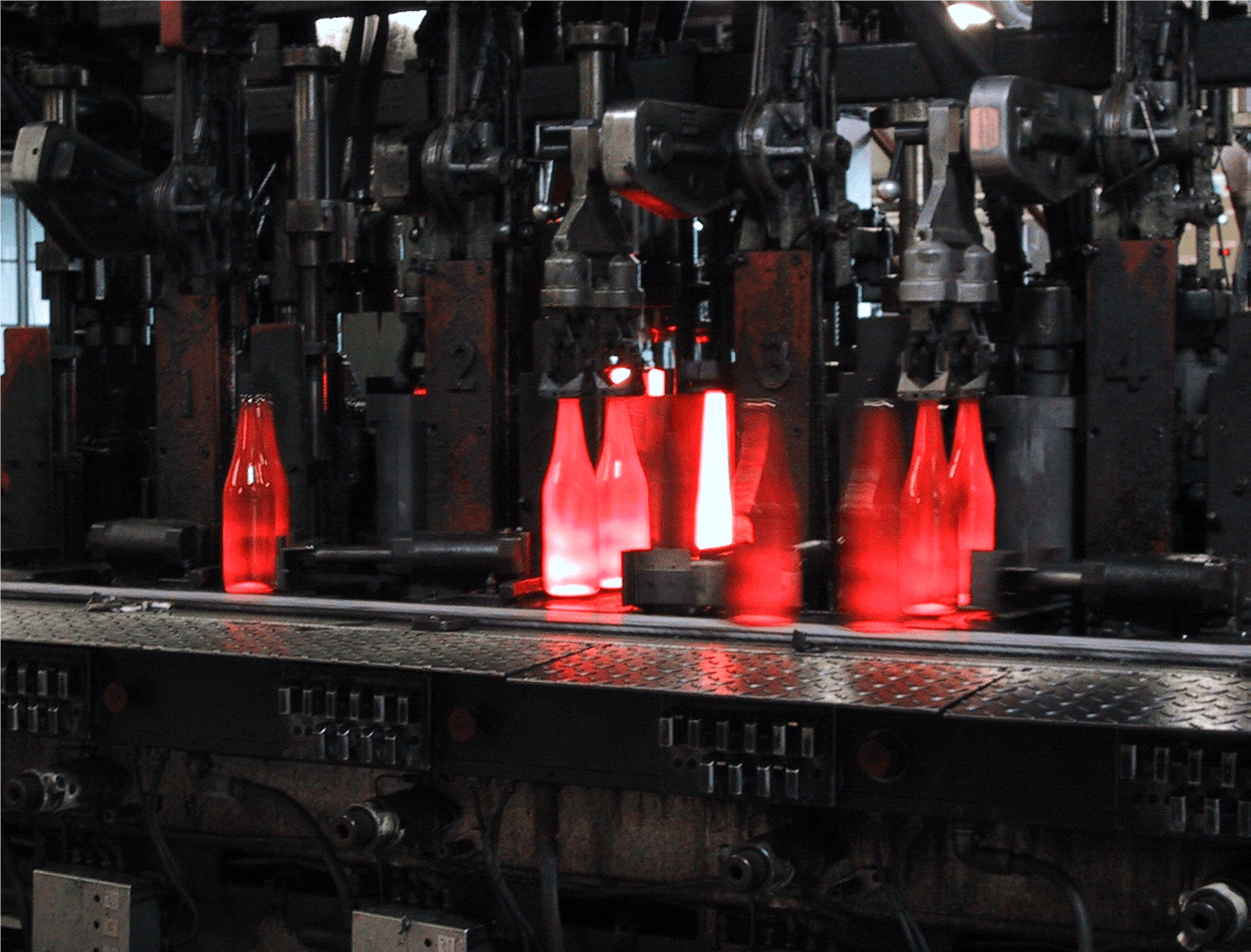

In the production of containers, the lehr time can be 30-60 minutes and it is therefore important to monitor IS machine performance before the lehr. The Hot End Trend Analyser (HETA) is designed to measure and inspect the containers just after forming.

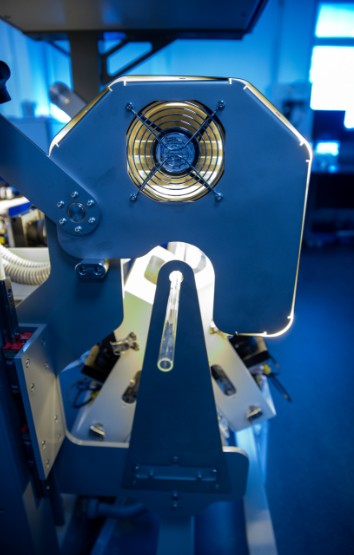

The vision system consists of a LED light box and 3 cameras mounted in water or air-cooled enclosures.

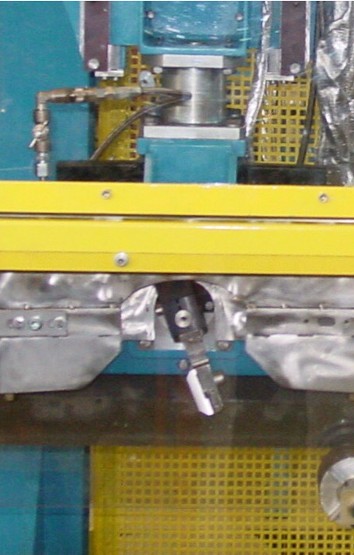

One camera measures the speed of the bottles and helps determine when to push the bottle if a reject has been installed.

The HETA automatically adapts to new speeds when operators increase/decrease the speed. The HETA can detect traditional surface defects such as dirt, stones, seeds, blisters, and birdswings and is capable of omitting the embossment on containers. The HETA meaures dimensions: height, 3 x diameters, lean, base and shape measurement.

As a feature it inspects for changes in material distribution and calculates the ware position. Trend statistics are generated for all forming tools and it enables the operators to focus attention on the tools causing trouble, and thereby substantially improve yield.

Why choose the JLI Hot End Container Inspection system?

- Ruggedized unit for hot end environment

- Increase yiel

- Comprehensive trend statistics for all forming tool

- Easy set up for new job

- Measure material distribution, surface and dimension defects

- Defect classification

Example systems in

Glass Inspection:

Designed and developed to meet high demands for speed and sensitivity.

Reduce waste by up to 40%

The system will continuously measure and inspect tableware as the glasses pass on a conveyor.

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)