Machine Vision for Wood Inspection

Wood Inspection

Improve quality and decrease wood inspection costs with advanced machine vision

Inspecting wood and wooden elements is a difficult task when done manually. Wood is organic and all items are basically unique. This results in high costs and variations in the inspection results.

Manual inspection of aesthetic qualities on products in the wood industry will typically capture about 70-80 percent of the defects. The problem can be both that items with defects slip through the control and that the human eye incorrectly discards items that are within the set standard.

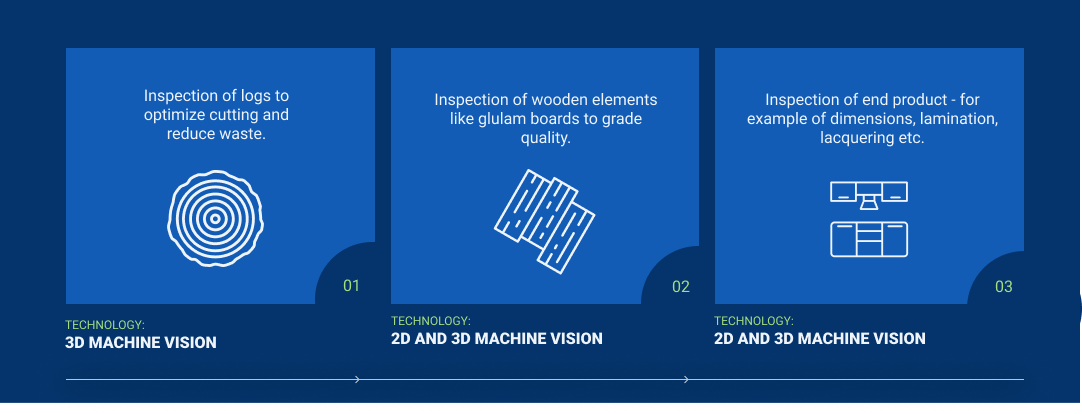

Machine vision can be used to optimize a number of processes in the wood industry - from sawing the log to quality inspection of the final product.

98% accuracy in wood inspection

JLI vision specializes in developing advanced machine vision systems for automating challenging inspection tasks, the type of inspection that would normally require a highly trained human eye.

By combining 2D and 3D machine vision with machine learning, we can automate the inspection of items that would otherwise require the assessment of experienced employees.

For example, when using wooden boards for quality furniture, it's very important to detect the knots that could cause holes or dropouts, before the board is processed in expensive operations. Some resin pockets can cause problems, as the resin will get more fluent, if the furniture is placed in warm surroundings. It is very difficult to distinguish between acceptable resin pockets and rejectable resin pockets.

To solve this task, JLI vision has combined machine vision and machine learning. We have trained a neural network with 30,000 images to determine which knots and resin pockets can pass a quality control

Another example is inspection of lacquered surfaces of wooden elements. With a combination of 2D machine vision, multiple cameras, and machine learning, we detect a wide range of different types of defects, e.g. holes in the surface, edge and corner damage, dust in the lacquer, glossy stripes, orange peel, etc.

This built-up knowledge of inspection in the wood industry is the foundation of the new solutions we make. We have documented success with 98% accuracy in detecting defects in challenging inspection tasks.

Why choose the JLI turnkey wood Inspection system?

By automating the inspection, you free yourself from the lack of reliability and predictability associated with human inspection. Your machine vision system detects the same way every time and does not get tired.

Reliability and scalabilityWith an automated inspection, you can easily scale your production and maintain the same high level of quality control.

Improved profitabilityBy reducing the ongoing costs of inspection and optimizing production - for example, by reducing waste and improving quality - you can improve your profitability.

Machine Vision for Wood Inspection

Improve quality and decrease wood inspection costs with advanced machine vision. Fill out the form and collect your wood inspection brochure.

This brochure will tell you how vision systems can be used for wood inspection in a wide range of processes in your industry.

Here are some of the pain points the brochure goes through:

- Streamlining the inspection process

- Detecting defects

- Improving quality control

- Automating the inspection process

When downloading the brochure, you also sign up for our Newsletter where you will receive offers, news, cases, and other relevant information directly in your inbox.

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting