Machine Vision for Label Inspection

Automate an extensive manual label inspection task

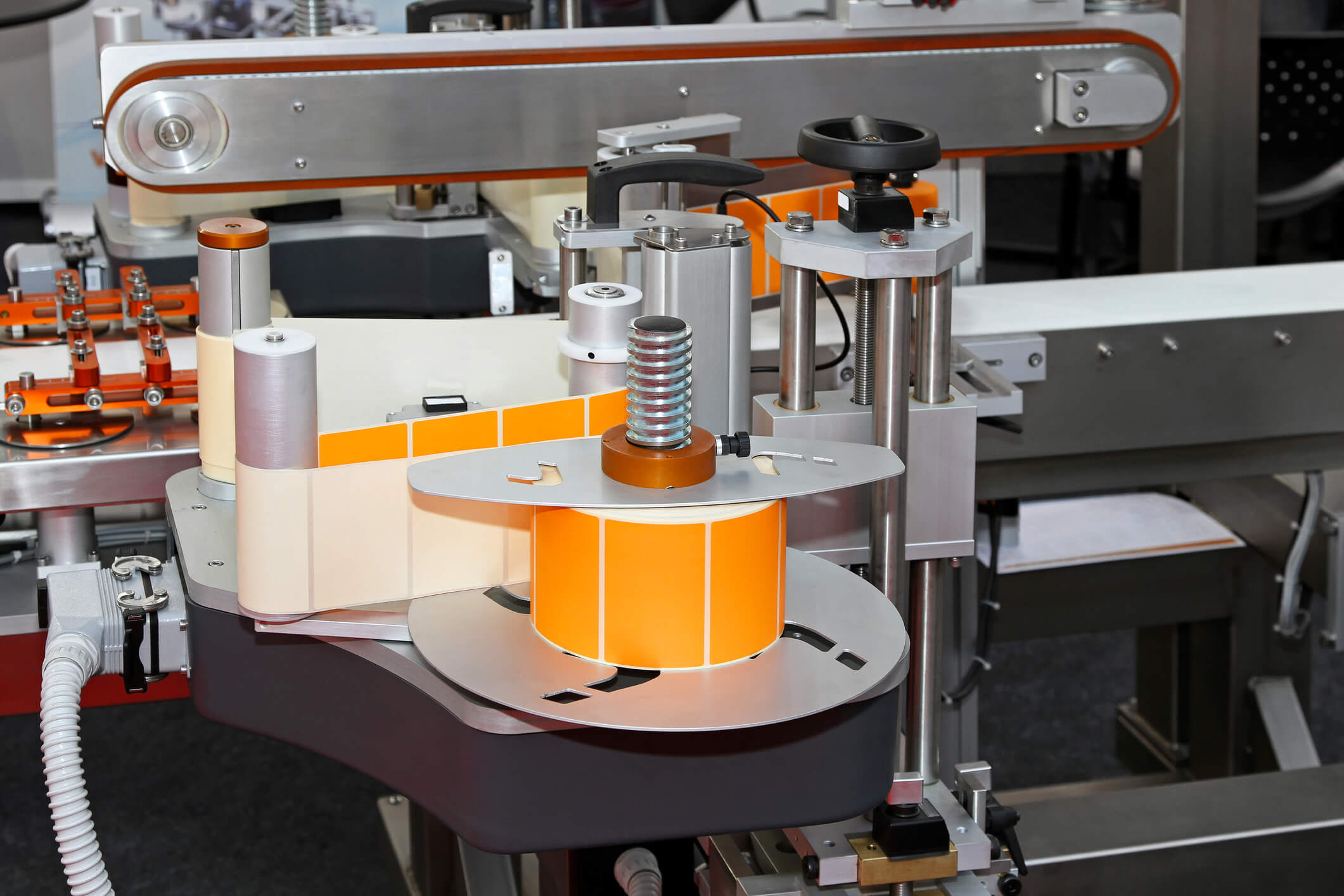

When labeling, it is necessary to inspect the final product.

Labeling machines cannot operate fault free and extensive manual inspection is often associated with this operation.

Typically today's verification of labels for clinical trials is carried out by manually checking each label.

An automated inspection system can detect the exact location and orientation of the labels. Any drift in alignment and the label is rejected.

The JLI Clinical Trials Label Inspection System is a stand-alone unit that automatically verifies all your printed labels, including variable text and barcode fields.

When a defective label is detected the operator is informed so that the label can be manually inspected and removed.

The inspection system will work with any printed language, as long as variable fields are ASCII characters.

The system is capable of inspecting labels with different colors and transparent labels.

Why choose the JLI Label Inspection System?

- Manual inspection is eliminated

- Fast and reliable results and trends

- Detects drift in positioning compared to a reference point e.g. an eyebrow

- Stand alone unit ready for conveyor installation

- Automatic rejection of defective labels

- Accepts printer imperfections

- High speed - One system can service many printers

- Compact and stand alone unit

- Improve your label quality by eliminating human “error”

Example systems in

Packaging Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)