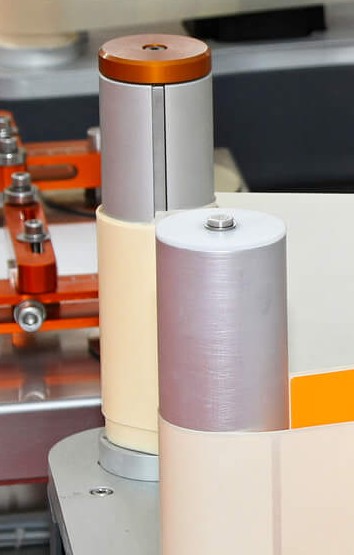

Machine vision for Print Inspection

Precise and flexible inspection of prints

A print must be placed accurately, with sufficient contrast, complete and readable. This is true for any industry.

This vision system inspects prints immediately after production. If any discrepancies are detected, the system can activate a reject mechanism. Statistical data is gathered and enables operators to follow any developing deficiency of the print.

Modern printers often work at a speed and complexity that makes it hard for operators to ensure the quality of each part or even to tell which components need attention when something goes wrong.

The JLI Print Inspection System is a 3rd generation vision system for 100% inspection of printed parts. The system is integrated into a stepped or continuous motion printer where it will inspect parts for print position, print quality, transparency, and dirt.

The integration enables immediate feedback on printer performance to the operator, and the vision system will continuously indicate the performance of each individual sheet, blanket, and pin to assist in quick debugging and adjustment of the machine.

Automatic feedback is also included, enabling the vision system to control the application of ink based on the measured density of the print. This will keep the print quality highly uniform without relying on operator time or skills.

Why choose the JLI Print Inspection system?

- Precise colour drift inspection

- OCR/OCV and evaluation of overall print quality

- Pattern recognition of images

- Flexible recognition rules

- Line scan or matrix camera applications

- 100% inspection

Example systems in

Packaging Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)