Building Industries

Machine Vision for Brick Inspection

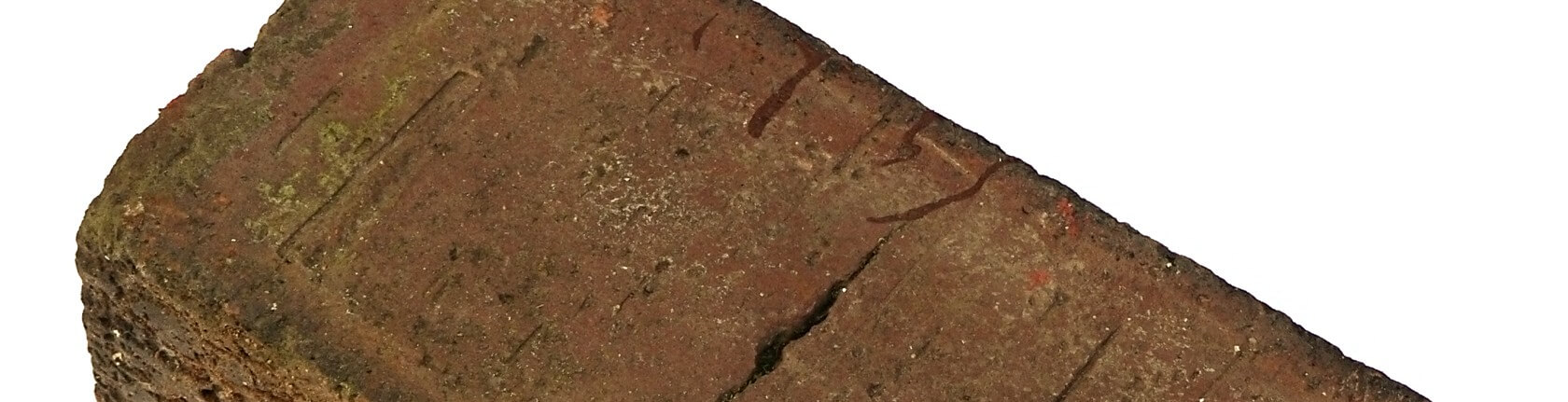

Automated quality inspection of building bricks

In the production of building bricks, manual inspection is often performed before the burning process.

Because of a very high production speed, manual inspection is difficult to achieve.

JLI’s brick inspection system provides 100% online inspection for measurements such as dimensions, surfaces, cracks, etc. An advanced surface inspection analysis makes it possible to classify bricks depending on their surface quality.

The inspection system can be integrated into existing production equipment and can be set up for automatic rejection of defective bricks by timing a signal. The system also provides process analysis by trend curves.

Features & benefits

Why choose the JLI Brick Inspection system?

- High speed operation with reliable results

- Advanced surface inspection

- Designed for dusty environment

- Replaces manual inspection

- Statistics showing trends and performance

- 100 % online inspection

- Flexible, compact and portable design

- Elaborate defect classification

Example systems in the

Building Industry:

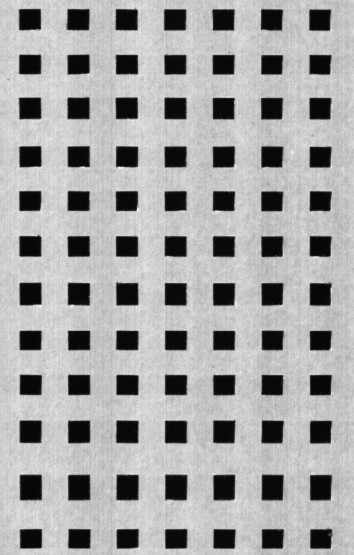

Board Inspection

Read more

In the production of different types of boards e.g. acoustic boards with a punched pattern or shelves, sometimes a repeating defect may occur, such as pressure marks, dimensional error, or positioning.

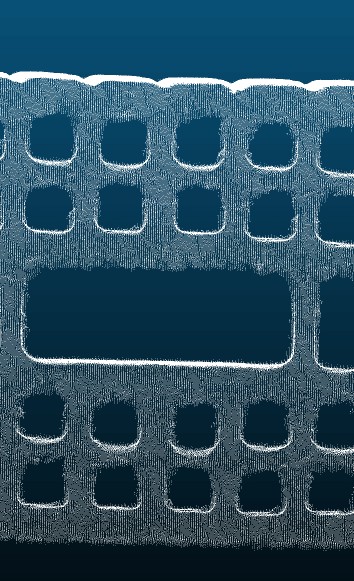

Hollow Brick Inspection

Read more

In the production of hollow bricks, it is important that certain dimensions are within tolerance e.g., width, height, depth, and bow.

Brick Inspection

Read more

This vision system inspects prints immediately after production. If any discrepancies are detected, the system can activate a reject mechanism.

Book a meeting to learn more

.png)

Henrik Birk

Sales Manager

Book a meeting here

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)