.jpg?width=1680&height=431&name=Board%20Inspection.front.%20(1).jpg)

Machine Vision for Board Inspection

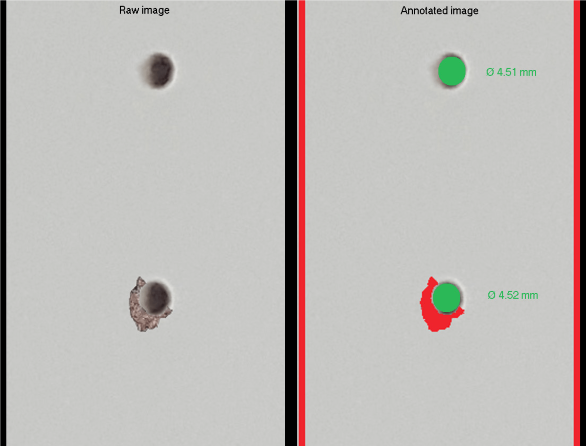

Automated inspection of patterns or defects in boards

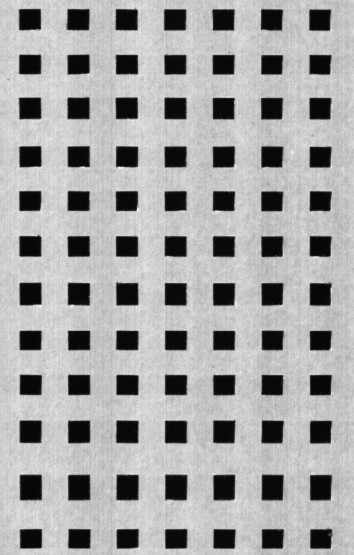

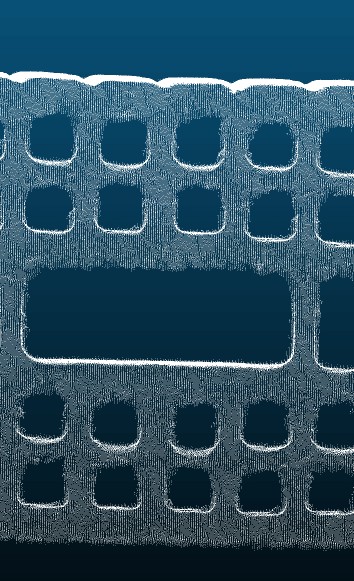

In the production of different types of boards e.g. acoustic boards with a punched pattern or shelves, sometimes a repeating defect may occur, such as pressure marks, dimensional error, or positioning. To detect these defects a vision system can be installed.

The system measures and verifies width, height, and all angles of corners. The entire surface is checked for discolorations and impurities. The predefined pattern of holes is compared to every board that passes the system. Any hole not completely punched or drilled out, or containing a scratch or mark outside the desired pattern will be detected. The position of each hole or pattern is verified.

Inspection is carried out inline with a capacity of 1 m/sec and a max. width of 800mm. Wider boards can be handled with a dual setup. The system can handle boards with any given pattern.

The system interfaces with any PLC, to automatically receive information about the board type and the current pattern. It collects statistical information and relays it to the factory network.

Why choose the JLI Board Inspection System?

- Measures any board such as plaster, glue, shelves, or acoustic

- Comprehensive trend statistics and report

- Easy setup for new jobs

- Option: Timed reject air nozzle

- Internet connectivity for easy support

- Measure impurities and dimensions/angle/pressure marks

- Defect classification

Example systems in the

Building Industry:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)