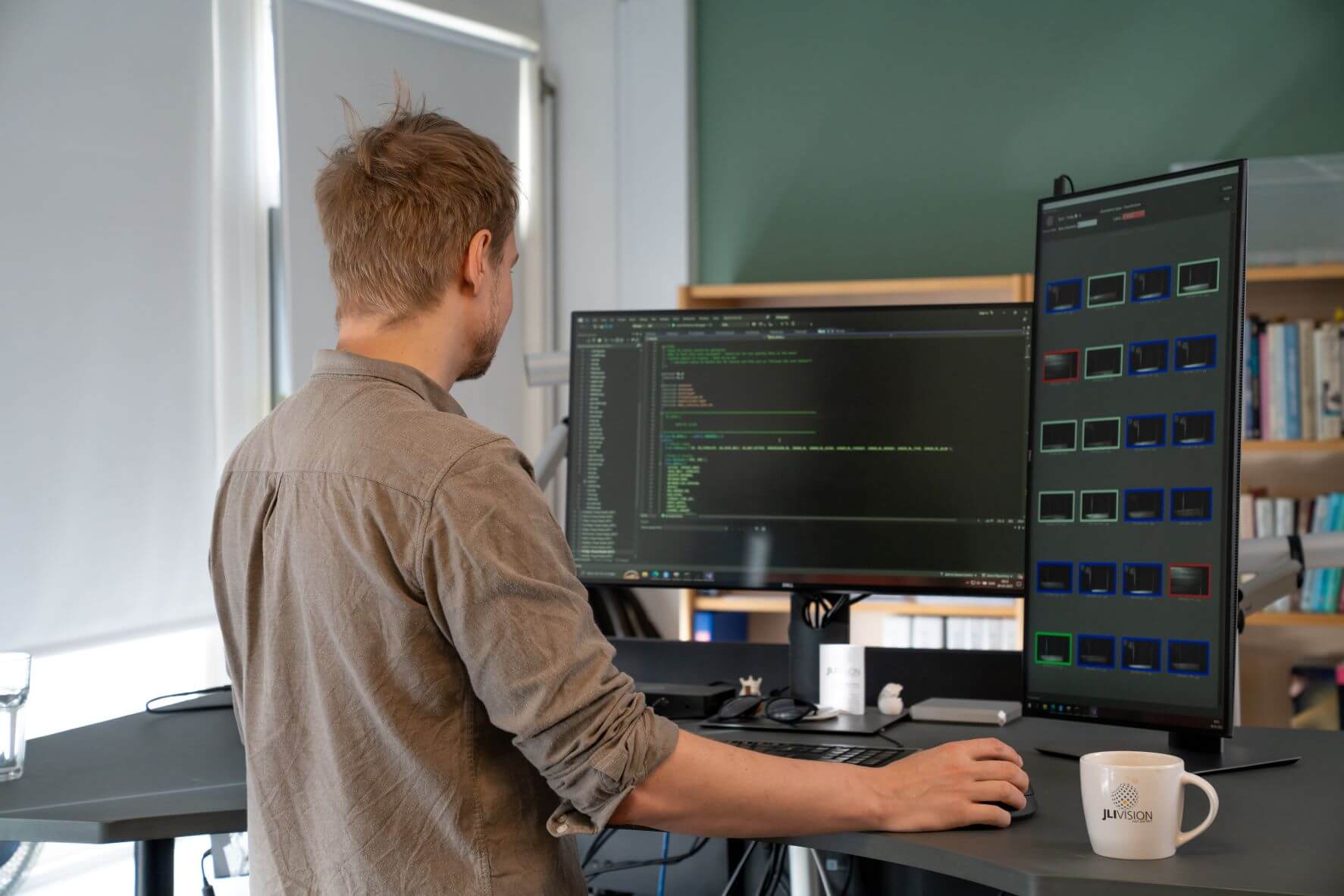

In 2024, JLI vision a/s has invested heavily in the development of vision technology in many areas.

The development has been done in collaboration with customers, but the company has also spent a lot of hours on research in fields that will be of great importance in the future.

Aluminum parts, glass carpules, and steelworks

One example is the development of vision technology for quality control of the very large cast aluminum parts that are starting to be used in the automotive industry. These very large parts require inspection from many angles as the areas to be inspected have complex shapes. Machine learning is an obvious choice, but how do you get the thousands of images with real defects to train on?

We have solved this problem by developing simulation software that can generate a digital twin of the part. This can be used to optimize the physical setup, but also to train the artificial intelligence so we don't need thousands of test items. We have received an order worth millions to investigate the possibilities.

In this context, Cognex (the world's largest smart camera manufacturer) has partnered with JLI for development, and JLI has become a "Partner System Integrator".

Growth from pharma and steel

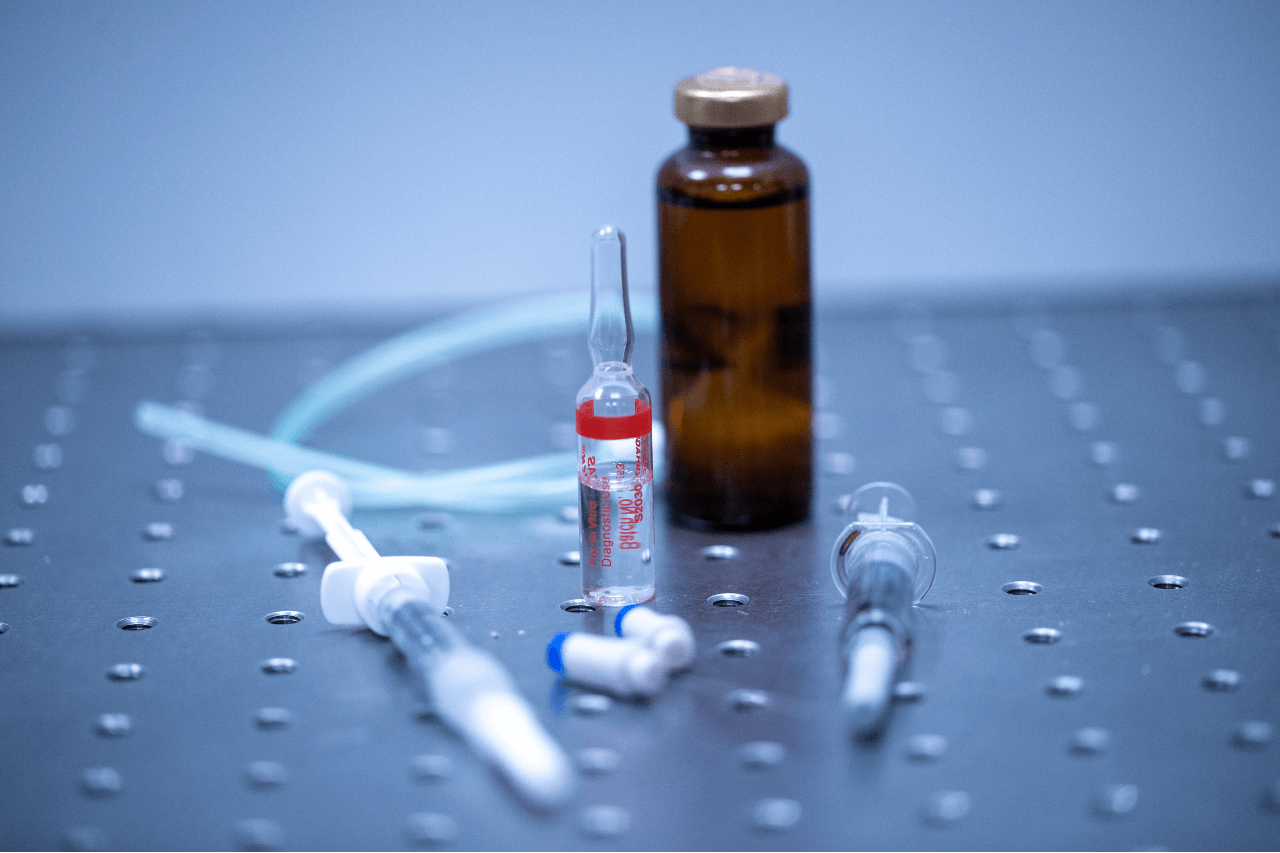

The pharmaceutical industry continues to grow in revenue, and this has led to a number of resale orders for systems we have supplied over the last 10 years.

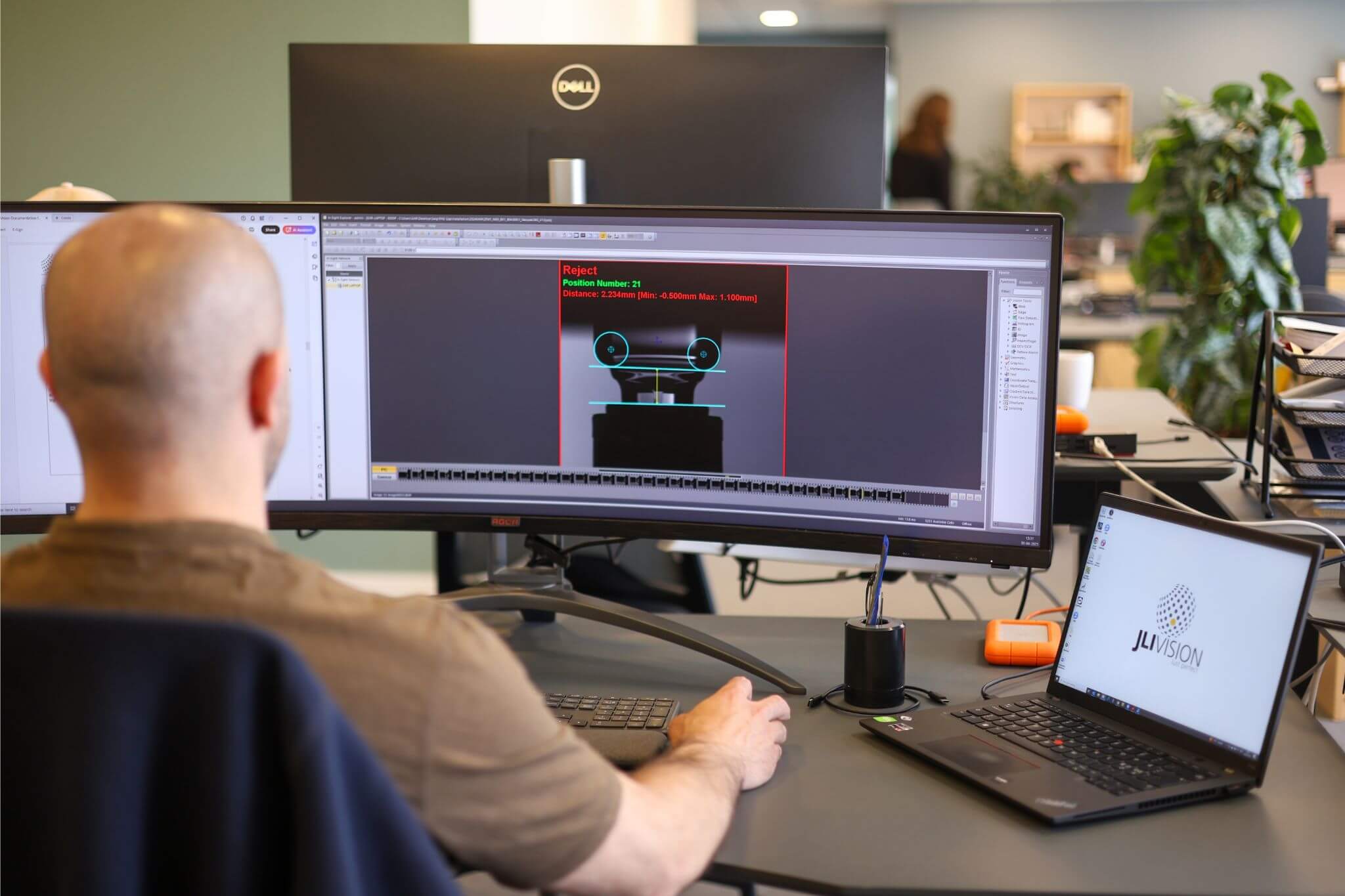

Growth in this area is around 30 percent per year. The systems are complex and have been developed over many years. The latest glass carpule crack inspection systems are now being developed with machine learning. We have ensured that the systems can be FDA-validated and thus approved for use in the medical sector. On the sales side, we have seen an increasing interest in our steelworks systems.

Vision technology for measuring is very useful in steelworks because you can usually keep the cameras at a good distance from the hot steel or use water-cooled camera housings. JLI has been developing vision systems for steelworks for almost 40 years. The latest ones use machine learning to detect surface defects on railroad rails right after rolling. This year, JLI has initiated strategic cooperation with steelworks in both Central America and Asia. We expect increasing activity in this segment.

Light lab expansion with spectral measurements

We have expanded our light laboratory with equipment for spectral measurements.

There is great potential in expanding inspection and measurement in the infrared and ultraviolet range, and we have helped several customers solve tasks that seem impossible.

Read more about spectral imaging here: Spectral Imaging