Automated surface inspection system

Eliminate manual inspection and improve quality with Surface Control AI

Better and faster surface inspection

Finding aesthetic or structural defects in surfaces is a difficult task even for experienced inspectors.

Manual inspection is time-consuming and imprecise compared to a modern machine vision system based on artificial intelligence.

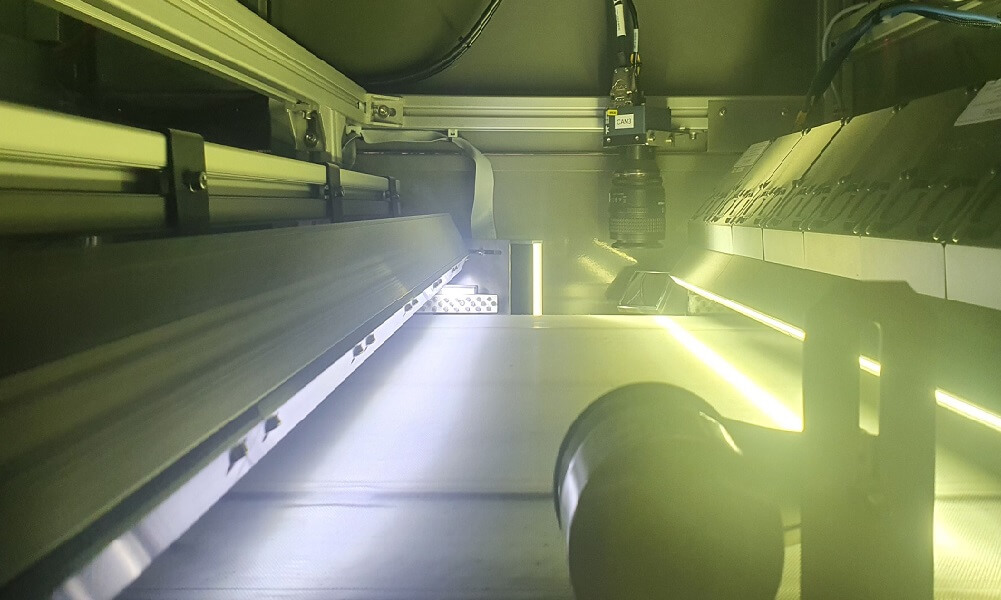

Surface Control AI is an advanced surface inspection solution that combines decades of engineering work with vision technology and the latest AI techniques.

It enables automated identification and classification of 25 defect types on various surfaces, from raw wood to painted and lacquered surfaces, metal, plastic, etc.

Benefits of Surface Control AI

- Improve product quality through consistent and accurate inspections

- Improve efficiency by automating labor-intensive manual tasks

- Improve yield by speeding up production flow and reducing discard

.png)

High-speed inspection: +50m/min (depends partly on product color). Allowing for an efficient production with high quality standards

.

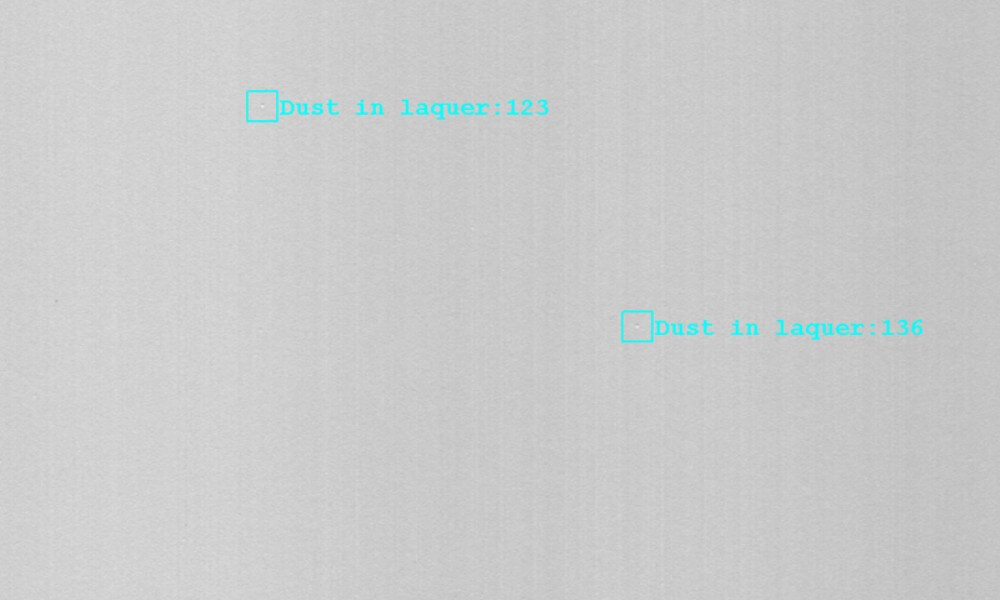

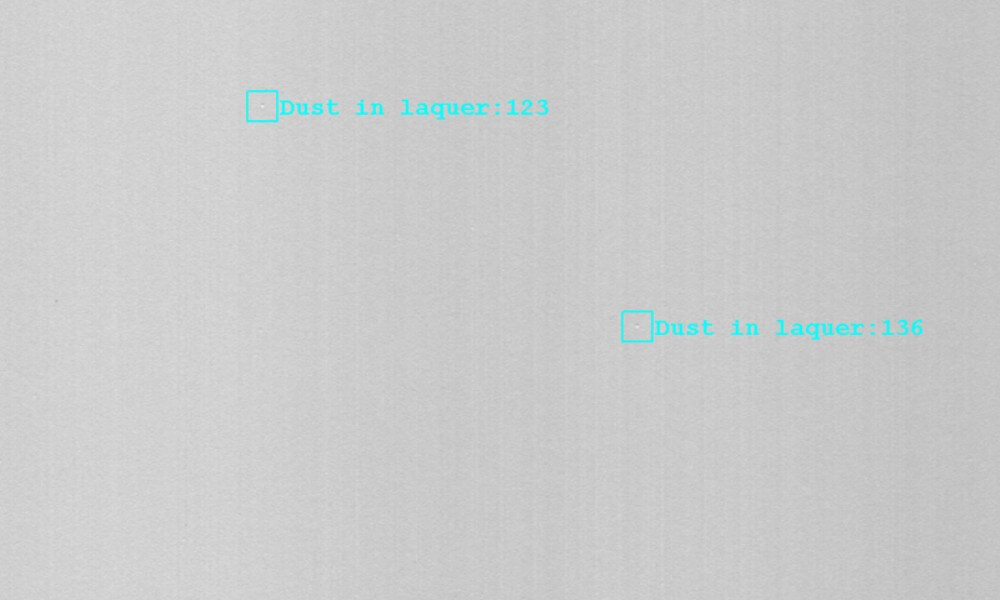

Finding challenging defects with AI

Artificial intelligence makes it possible to detect and classify very complex defects like orange peel, glossy stripes, scratches, etc.

By training a neural network with images of good and bad samples, we can use machine learning to mimic the experienced inspector's assessment and achieve a more consistent and accurate inspection process. We use our automated annotation software to speed up the training process.

Unlike a standard all-in-one AI solution, Surface Control AI can handle complex inspection tasks that require customisation and a deep insight into the use of machine learning and vision technology.

Valuable insights from your production

The system provides valuable insight into production quality and can help monitor drift, as well as compare suppliers of raw materials and products.

Surface Control AI also offers the ability to generate statistics and trend graphs.

Adapted to your needs

Every Surface Control AI system is tailored to meet your specific needs and fit into your production line.

The system can be configured to inspect both surfaces and edges.

Surface inspection system specifications

Surface Control AI is built on premium hardware and software fitted to your needs.

- Camera(s): Industrial high-resolution CCD

- Computers: Industrial vision PC’s

- Monitor: 23” touch flatscreen

- Automated annotation software

-

Interface: Digital I/O, EthernetIP, ProfiNet, OPC-UA

- Motorised cameras for flexibility

- Speed of inspection: 0-100m/min

- Thickness of inspected item: 10-50mm

- Width of inspected item: <1000mm (can be customized)

- Can be customized to inspects both surfaces and edges.

- Inline inspection. Supports conveyor belt, roller, and other transport systems.

- Developed and validated according to GAMP5

Surfaces that can be inspected

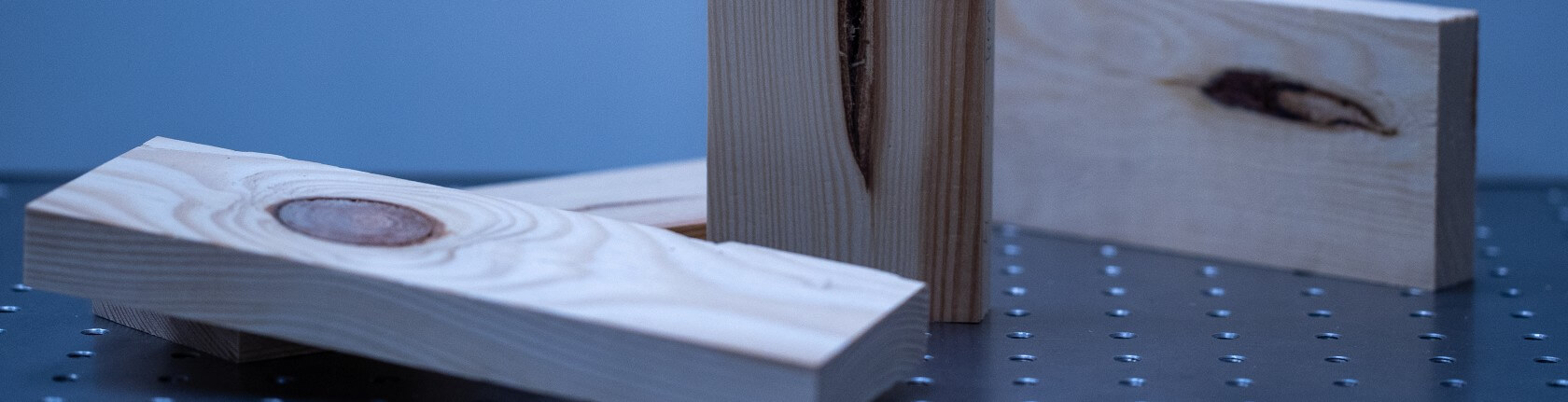

Surface Control AI is highly versatile and can be applied to a number of different materials, each with it's unique set of challenging defects.

- Laquered or painted surfaces

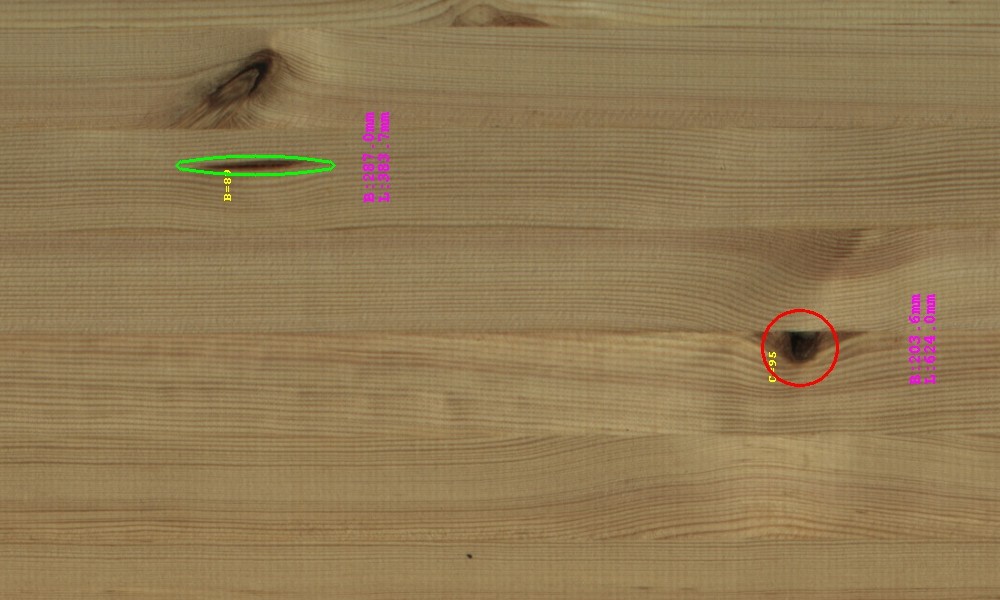

- Wood

- Metal

- Plastic

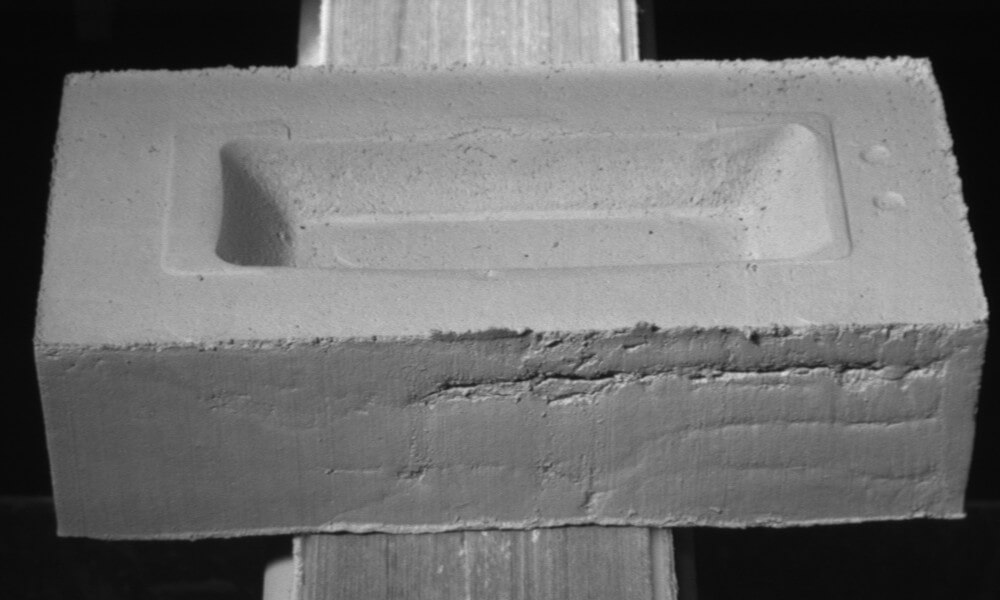

- Bricks and other building materials

Findable defects

Surface Control AI can detect and classify more than 25 different defect types, like:

- Hole in surface

- Edge/corner damage

- Dust in lacquer

- Dirt

- Scratch

- Paint residue

- Pinholes

- Orange peel

- Rough edge

- Roller marks

- Silicone spots

- Scratches from burning

- Glossy stripes

- Etc.

Pricing

From 98.000 euros.

Including customisation, implementation, and training.

Download Surface Control AI brochure

This brochure will tell you how Surface Control AI can help you:

- Improve product quality through consistent and accurate inspections

- Improve efficiency by automating labor-intensive manual tasks

- Improve yield by speeding up production flow and reducing discard

Fill out the form and get your brochure. When downloading the brochure, you also sign up for our newsletter.

Book a meeting to learn more:

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting