Signify

Securing and optimizing the inspection of glass tubes for Signify

Signify has been using inspection systems for years, but as the need for inspection changed, the old systems no longer met the demands.

Another problem with the old equipment was that there was no longer any support from the manufacturer and spare parts were no longer available.

Signify is one of the world's largest manufacturers of lighting including a wide range of bulbs and light tubes.

The main factory is located in Poland, but has a worldwide presence including factories outside Europe.

“We have noticed a significant improvement in our production process since implementing SK-2130. The system’s advanced features have helped us streamline our operations and maintain a consistently high level of quality in our production."

A new cost-effective inspection system with continuous support

Solving this problem required a more advanced setup than a traditional machine vision application - what JLI vision refers to as “hybrid vision”.

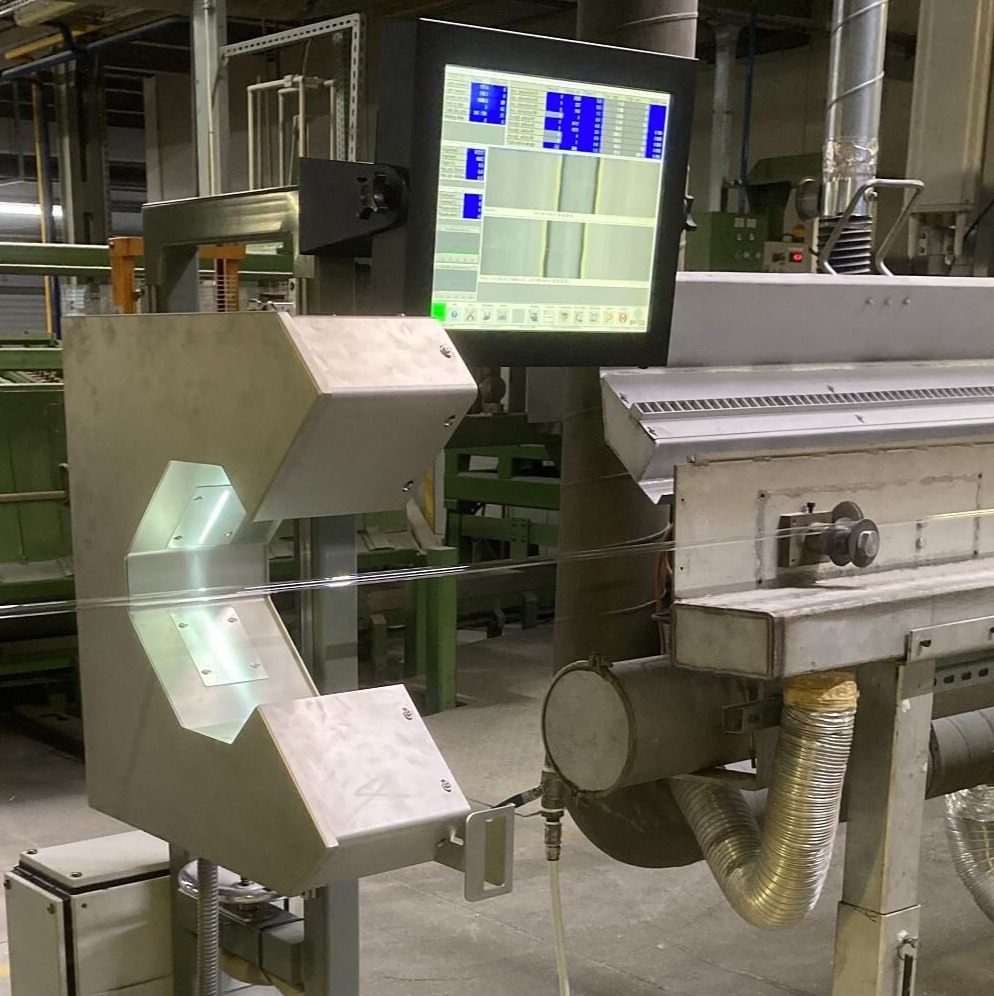

JLI vision developed and installed the latest member of the SK-3000 series of in-line tube inspection systems.

The new system is called SK-2130 and is optimized to work on lines with a lower WT/OD ratio than typical pharmaceutical lines. This means that only 2 cameras are necessary instead of 3 or more.

Together with other optimizations, this brings the price of the system down. Another important improvement is that this system uses LED light instead of sodium bulbs.

As sodium bulbs are the single most power consuming component of the standard SK-3000 series systems, the power consumption for light has been brought down with more than 90%. With other improvements mainly by using a new computer and other components with a lower power consumption, the overall power consumption has been reduced with approx. 90% compared to the standard SK-3020 system.

JLI is currently focusing on reducing the carbon footprint (CO2 emission) of our products. Mainly because of the significant reduction in power consumption, the carbon footprint of the new SK-2130 has been reduced by more than 85% when the full life circle of the system is taken into account.

A significantly better measurement accuracy

By shifting to equipment from JLI vision, continuity in support would be ensured, as JLI vision is the leading supplier in the market for in-line tube inspection with a very long track record.

The new system is a stand-alone unit and can therefore easily replace older equipment and interface with line control equipment without the need for changing any interface or software.

Actually, you can replace older equipment and have the new JLI vision inspection running within only one hour. The new equipment also has a significantly better measurement accuracy, so both the false reject and false accept rate are now better.

"We are happy with our investment in this equipment and would

recommend it to other businesses.

The customer support team at JLI vision has been helpful and responsive.”

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)

Download the case study

Can we help you, too?

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting