What a year 2020 has turned out to be! Looking back, it really has been like a rollercoaster ride here at JLI. Going into 2020 we set our aim higher than ever, but a certain pandemic made us doubt if this was achievable in spring time. Standing at the threshold to 2021 we now know that 2020 has been the best year in the history of JLI. We are seeing an increase of 20% in the turnover, basically growth in every aspect. We said hello to 4 new employees and are entering 2021 with many new exiting orders.

Looking ahead at 2021 we firmly believe that inspection, quality, automation and traceability will continue to be the focus of our customer - perhaps even more so – because the pandemic will continue its grip on the world for the foreseeable future. That’s also partly why we are confident that the machine vison industry will have a prosperous 2021.

Existing technologies will continue to develop and evolve in 2021 and we are certain that new ones will see the daylight. Like previous years JLI are focusing on development of rising technologies both existing ones and new ones. Here is our take on the most interesting ones.

Machine Learning (ML)

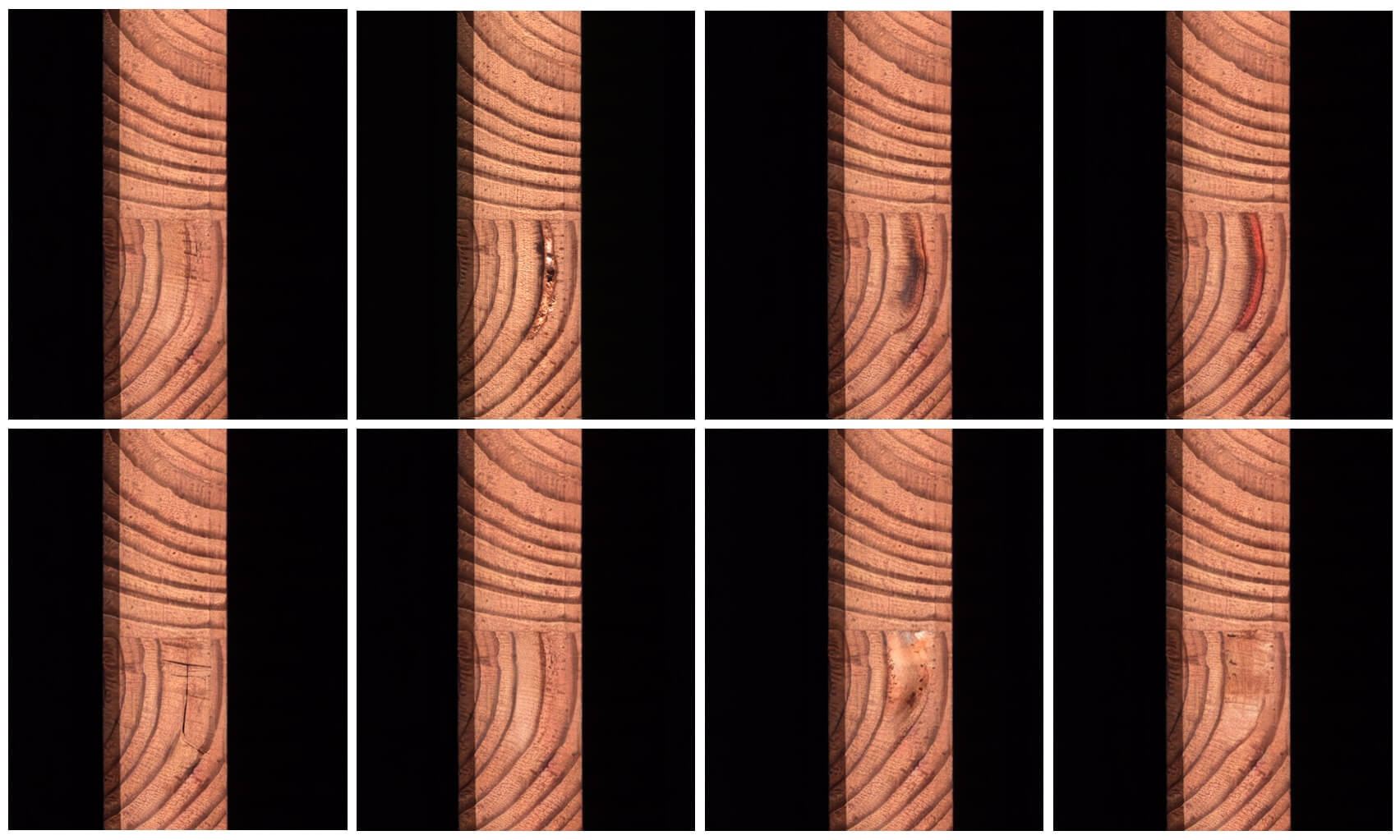

In 2020 JLI solved numerous applications using ML and in different industries. It seems like we are still only seeing the tip of the iceberg of what ML is capable of doing within machine vision. In the years to come JLI will challenge the ML technology and work to figure out new potential ML applications. JLI is researching the possibilities of combining traditional rule-based methods with ML to perform advanced surface inspection on difficult blank objects such as plastic, aluminium and painted objects. This is an application that can advance the inspection level and automate many manual inspection processes. JLI will also invest heavily into making tools available for customers to re-train existing networks. This will enable customers to add e.g., new defect types on the fly in inline production. The goal is to provide flexible, adaptable solutions, targeted at your application, and at significantly reduced costs.

3D

3D has been around for many years. Different technologies have surfaced making the use more widespread. JLI believes that 3D has an important part to play in the future. Three areas primarily open up: bin picking, depalletization and quality inspection. The key to increasing the adoption of 3D is to make the technology as simple to use as possible. Combine that with further developments providing more robust and reliable data under changing circumstances in the environment – the lighting – JLI expects to see a switch from 2D to 3D in many quality inspection tasks. Being able to measure dimensions inside as well as outside on challenging objects inline in production has a huge potential. We are not far from doing that.

Vision as-a-Service (VaaS)

Many will probably say: ”WHAT”, is this just another trendy word – only time will tell! The X-as-a-Service” is a rapidly growing field. It is devoted to providing services through cloud-based, on-demand platforms. For VaaS the objective is to determine what is happening in front of a camera and use that understanding to control a computer or robotic system. So far applications include video surveillance, biometrics, automotive, photography, movie production, augmented reality, gaming and machine learning. Running vision systems in the cloud, enables algorithms to interoperate with each other. Simple APIs can open new horizons to machine vision applications. As the ongoing pandemic rages around the world, we have clearly seen that companies that rely on a cloud to provide a scalable solution ’as-a-service’ are prospering. Perhaps VaaS will also open up an opportunity for customers and suppliers to deal with each other in a different way. The payment for a machine vision system could be comprised of how many items are inspected instead of a fixed price, making the financial side much more flexible for customers.

Please bear in mind that not all machine vision applications call for implementation of the latest and new trending components/technologies. Often new components/technologies act as just another tool in the belt, that together with traditional machine vision will help solve your application.

At JLI we try to maintain a solid perspective with respect to new components/technologies that continue to enable more productive manufacturing for our customers.