The quality control challenges in the manufacturing industry are numerous and complex, but an advanced machine vision solution can help solve many of these challenges.

The quality control challenges in the manufacturing industry are numerous and complex, but an advanced machine vision solution can help solve many of these challenges.

The primary challenge is of course to ensure accurate and consistent product quality, which requires close attention to detail at every stage of the production process. In addition, manufacturers must also be able to detect defects in their products quickly and efficiently, so that quality is never compromised.

Another key consideration is the need for timely and efficient production. Manufacturers face constant pressure to meet deadlines and generate high volumes, without compromising quality or incurring excessive costs. To achieve these goals, manufacturers must continuously evaluate their processes and identify opportunities for improvement.

At the same time, quality control challenges in manufacturing extend beyond just production itself, with the need to minimize waste being an important focus area as well. Whether it's wasted materials or excess energy use, companies must do everything possible to reduce waste at all stages of the manufacturing process if they want to stay competitive in today's market.

Let's take a look at how these challenges can be met with the use of advanced machine vision.

1. Ensuring accurate and consistent product quality

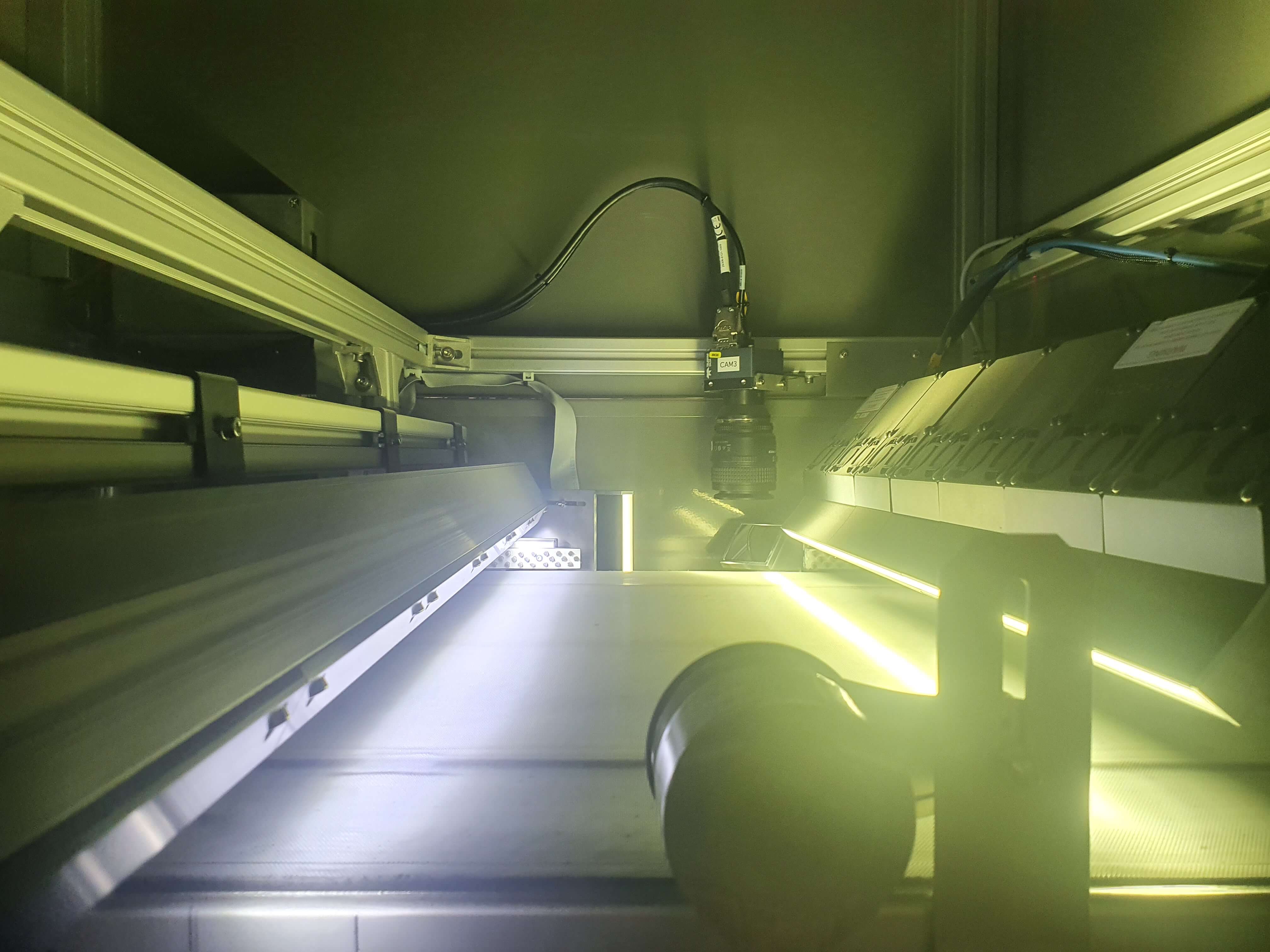

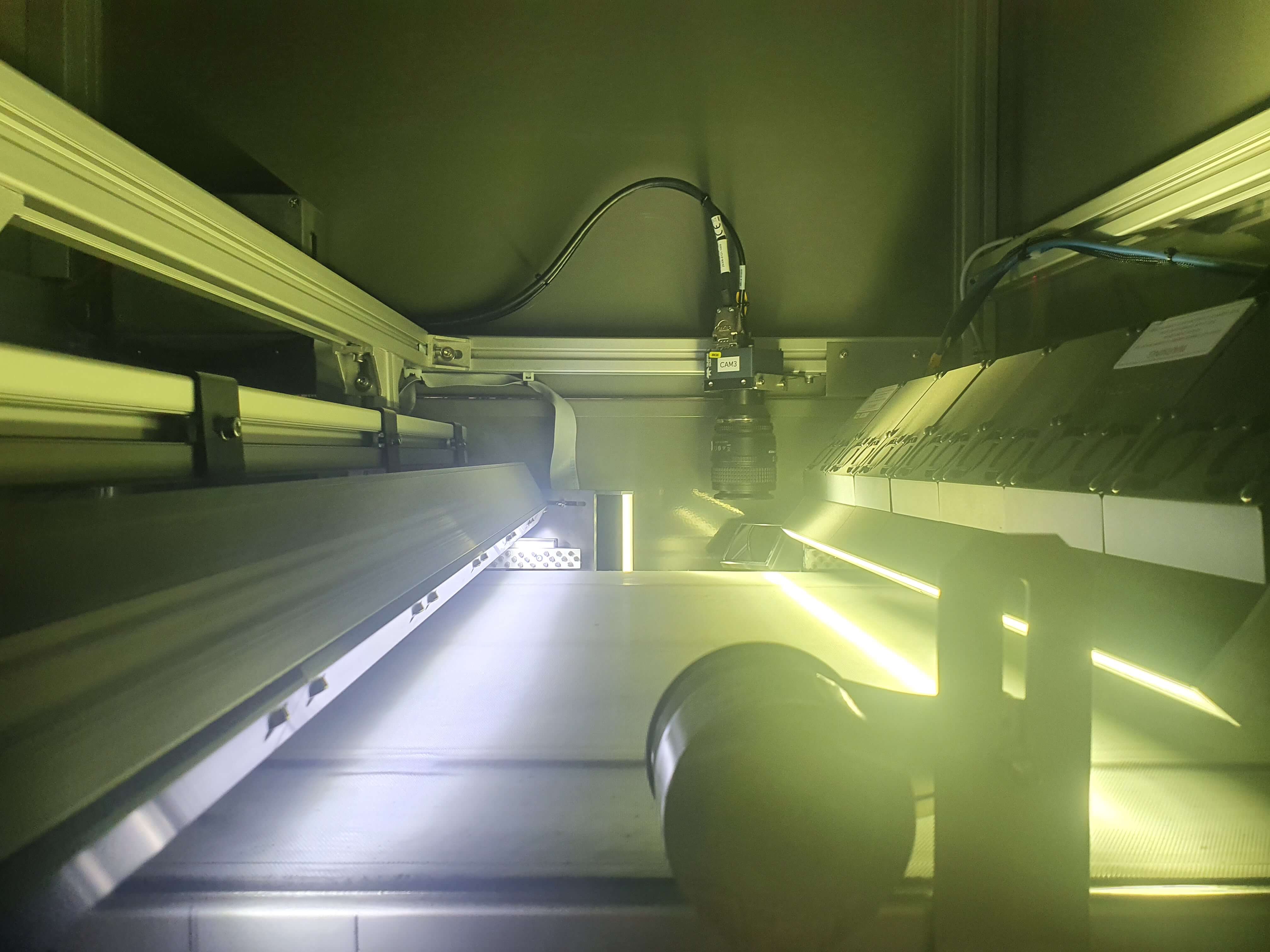

Machine vision is a powerful tool for ensuring the accuracy and consistency of product quality on the production line. Using machine vision, defects in products can be identified and corrective action can be taken immediately, minimizing the risk of costly errors or defects reaching the end user.

Additionally, machine vision provides real-time feedback to the production line, allowing operators to make adjustments quickly and effectively as needed. Through its ability to identify errors and provide feedback in real-time, machine vision is a powerful tool for improving product quality on the production line.

2. Detecting defects in products

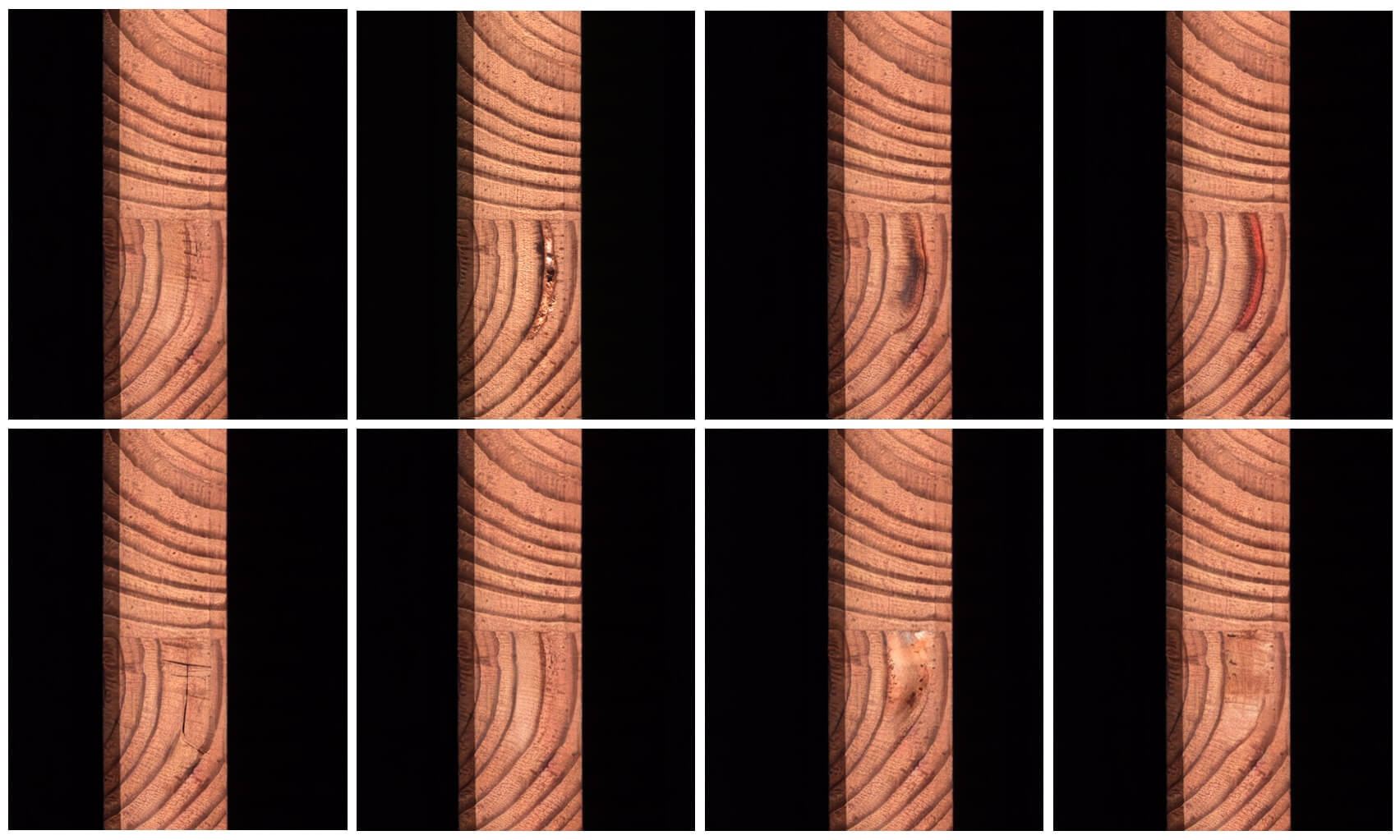

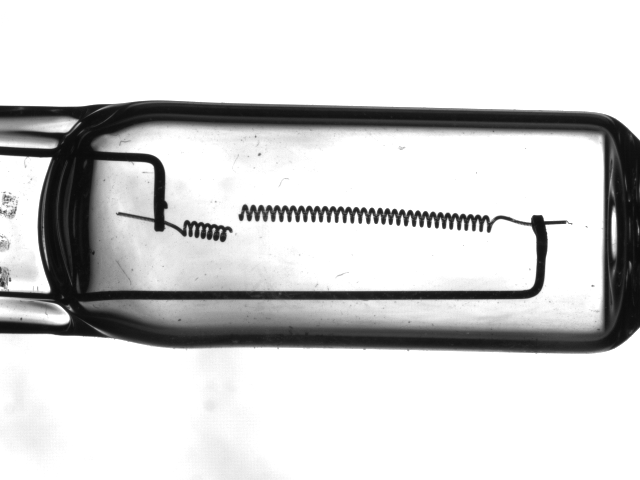

At first glance, it might seem that the human eye is more adept at detecting defects in products than any machine. However, research has shown that when it comes to speed and accuracy, machine vision is much more effective. This is due, in large part, to the fact that a machine never gets tired or distracted as a human does. With consistent and reliable performance, a machine vision solution can quickly and accurately detect even the most subtle imperfections in products of all kinds.

Moreover, because these systems use advanced image analysis software, they can evaluate visual cues far beyond what the human eye can see. Whether it's minute flaws in the appearance of a product or internal defects that would be difficult for an inspector to spot with the naked eye, a machine vision solution can reliably identify any issues at critical stages of production. As such, using this technology is often the most efficient way to prevent costly quality issues down the line.

3. Ensuring timely and efficient production

By automating time-consuming manual inspection tasks such as checking for defects or measuring product dimensions, machine vision can dramatically reduce the amount of human labor required in these processes, freeing up valuable resources that can be allocated elsewhere and avoiding human resources becoming a bottleneck in the quality control process.

In addition, machine vision systems can be easily integrated into existing production lines with minimal disruption, making them an ideal solution for improving efficiency and maximizing productivity in any manufacturing setting. Overall, machine vision has proven to be an invaluable tool for guaranteeing the smooth and successful operation of modern manufacturing facilities.

4. Reducing manufacturing costs

By eliminating some of the manual labor in the quality control process, machine vision can help manufacturers reduce their overall costs by saving valuable time and labor.

In addition to automating individual production tasks, machine vision can also provide real-time feedback about quality control issues on the production line. This instantaneous feedback helps managers quickly identify problem areas and make any necessary adjustments to improve efficiency or output.

5. Minimizing waste

Additionally, machine vision can help minimize waste on the production line. By detecting defects in products at a very early stage, machine vision systems allow manufacturers to identify defective items and address problems before they become costly and time-consuming.

Machine vision systems also help increase the accuracy of quality inspections, reducing the number of good products that are scrapped due to human error.

Machine vision has become an essential tool in the modern manufacturing industry.

By automating time-consuming manual tasks, reducing manufacturing costs, and minimizing waste, machine vision systems have proven to be a valuable asset for manufacturers of all sizes. In addition, real-time feedback from machine vision systems helps managers identify and address quality control issues quickly and efficiently, ensuring that products are manufactured to the highest standards.