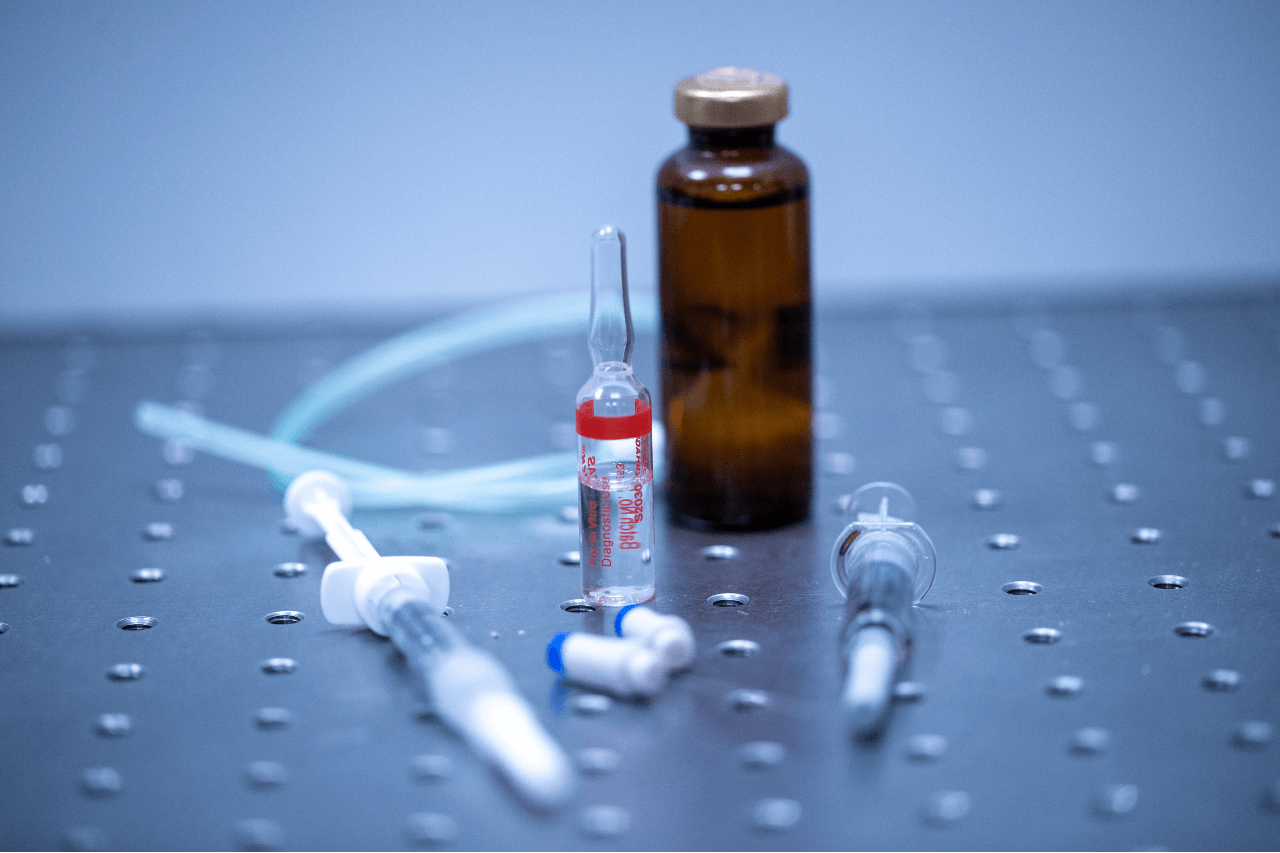

Within industrial manufacturing, few sectors are as demanding as the medical industry. The medical field demands extensive documentation of not just the solutions but every phase of the development process. This meticulous approach underpins the reliability of essential items like syringes, ampoules, and medications.

The Food and Drug Administration (FDA) sets the bar high for the medical industry, dictating stringent requirements for documentation throughout the development process. Achieving FDA approval hinges on this comprehensive record-keeping.

A detailed URS serves as the backbone

The first step is defining the solution's requirements, a very meticulous process where all requirements are mapped out and where a detailed risk analysis is carried out. This focuses on identifying potential failures, mitigation strategies, and response plans.

The requirements are documented in the User Requirements Specification (URS), a document that works as the project's backbone. This document is constantly referred to throughout the process, from solution design to construction and testing, ensuring every step aligns with the initial specifications.

The ability to baseline is key

The key to managing this process is version control, ensuring traceability throughout the development stages.

Equally important is the ability to 'baseline'. This means locking in mechanical and electrical settings, and documenting their state. This makes it possible to measure performance up against this baseline and document that everything is working in the exact same way as when the system was initially tested and deployed.

GAMP-5 guides the way

To guarantee adherence to regulations, we follow GAMP-5 guidelines. GAMP-5 stands for "Good Automated Manufacturing Practice," the latest set of guidelines focused on ensuring quality and compliance in automated manufacturing, particularly in the pharmaceutical and medical sectors.

Some of the key principles in GAMP-5 are:

- Risk Management: Prioritizes identifying and mitigating potential risks throughout the system's lifecycle.

- Product Quality and Patient Safety: Ensures products meet high standards and are safe for patient use.

- Science-based Quality Assurance: Grounds quality assurance in scientific principles.

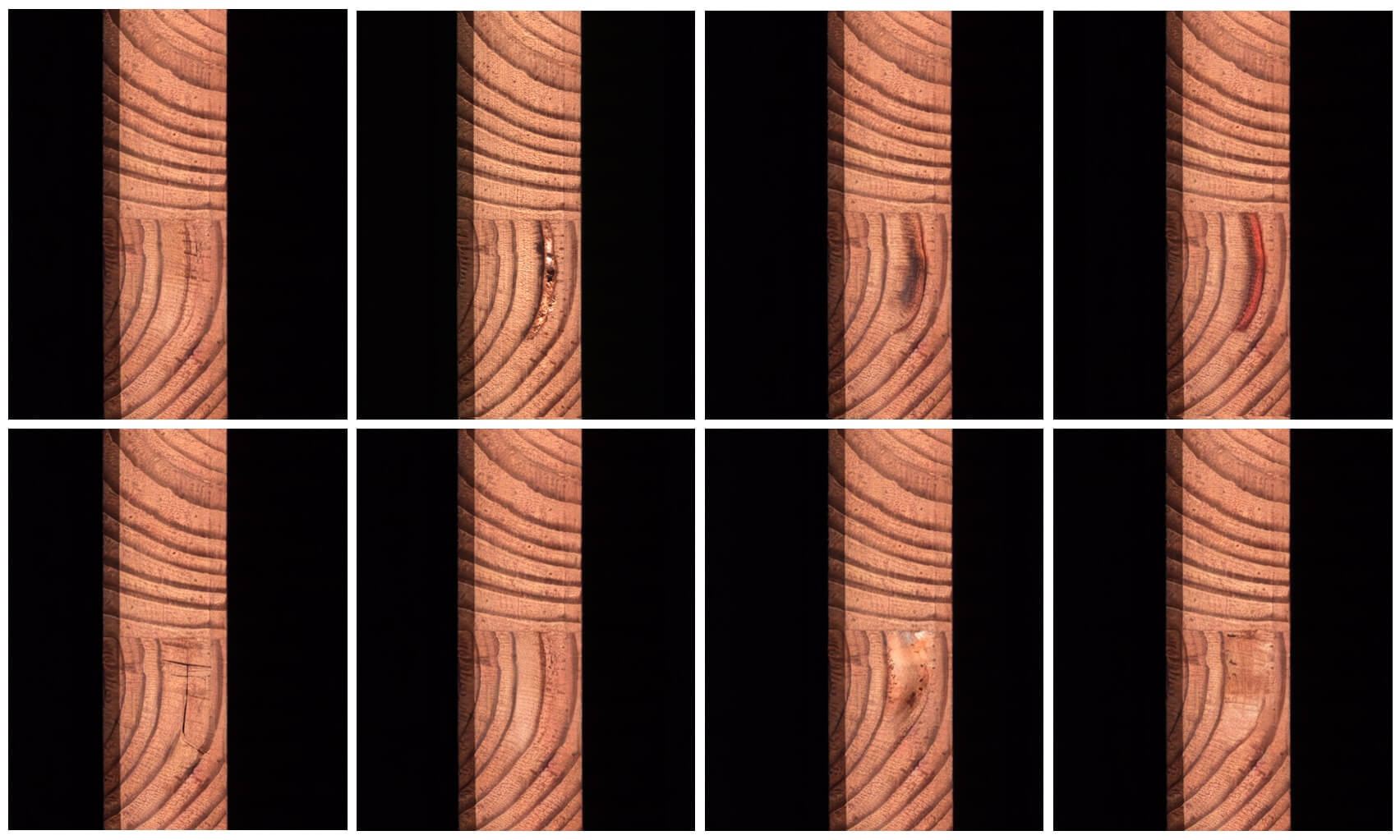

Tackling the Technical Challenges

Beyond documentation, the medical industry presents some unique technical challenges:

Light Exposure Limitations

Some ingredients are sensitive to light, necessitating specialized design considerations to limit light exposure.

Cleanroom Quality Control

Equipment used in cleanrooms must avoid design features that could harbor dust or contaminants. They must also be alcohol-wipeable and, in some cases, withstand hosing down.

Cold Room Operation

For inspections in cold rooms, the equipment must endure low temperatures over extended periods.

Zero Margin for Error

Above all, the medical industry's tolerance for error is virtually non-existent. Patient safety is paramount, making the rigorous requirements specification and risk analysis foundational to designing a fail-safe system.

All in all, developing machine vision systems for the medical industry demands an unparalleled level of precision, thorough documentation, and adherence to stringent standards. However, by understanding these requirements, it is possible to create systems that meet the demands of this critical field.