30 years ago Carlsberg asked us to develop a system for inspecting beer crates.

The breweries wanted two different inspections in order to avoid production stops on the bottling lines, and to ensure that the right crates were used. It was not good if a crate from a competing brewery was allowed to enter the line and eventually come out in the other end with beers in a wrong crate.

On arrival the crates are automatically emptied and washed. The next stage is inspection where a camera looks down in the crate to find stuck bottles or debris. Also the top of the crate is analysed to find broken handles. A second camera identifies the brand name on the side of the crate. Getting wrong crates back to the bottling line is a very Danish problem. Our standard 30 piece plastic crate is used by everyone. Abroad it is very different. The drivers delivering the beer crates to retail will only take their own crates back.

Getting wrong crates back to the bottling line is a very Danish problem.

Our attempt to sell the crate inspection in UK and Germany was a total failure.

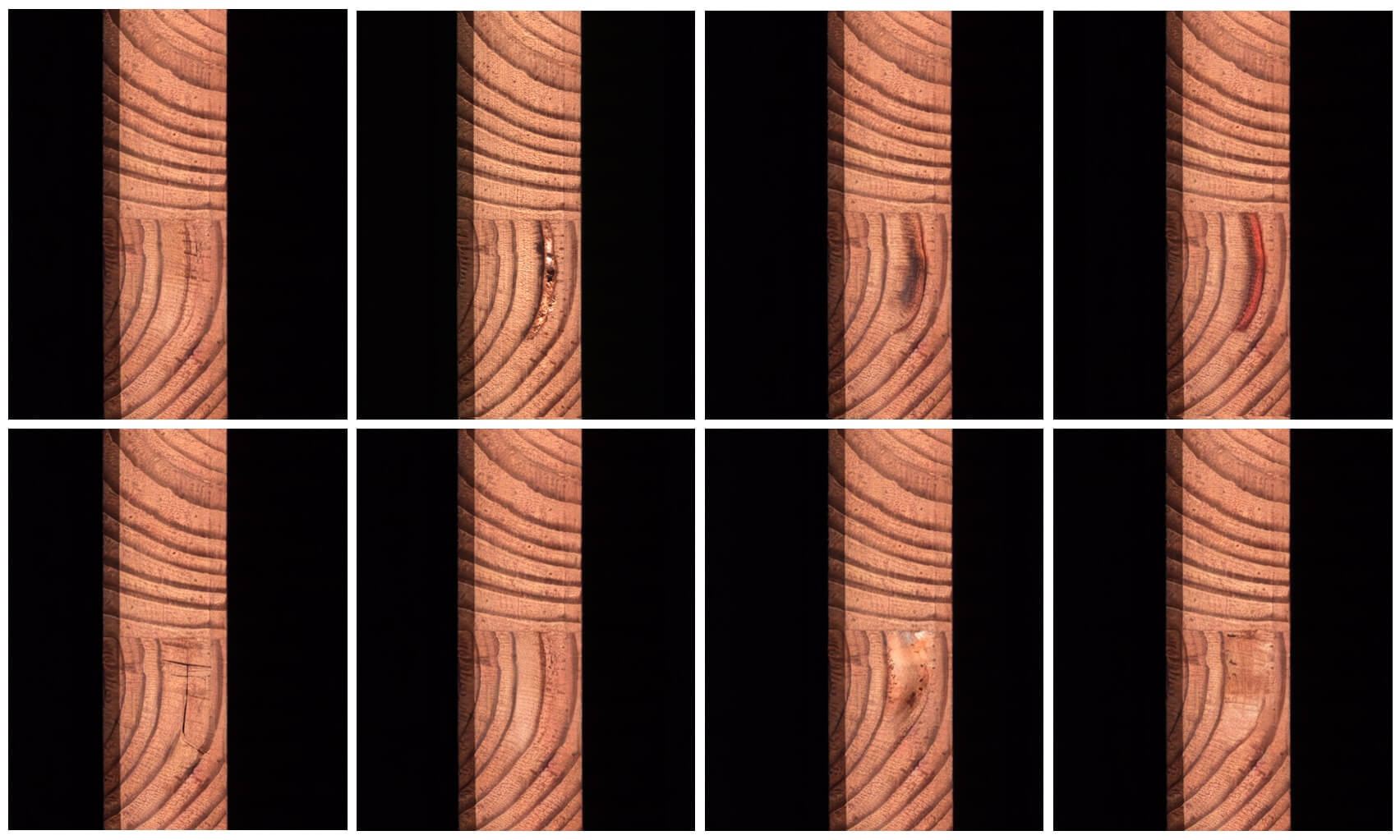

It took a long time before I realized why. The crate inspection is quite difficult. The main challenges are all the dents and defects that are acceptable, and the small defects that are critical. An aligned but broken handle will only show a minute crack. It can cause severe pain when lifting the crate. If the handle opens and closes again it can take a good bite of your hand.

We delivered more than 20 systems over the years, but today most beers are delivered in cans.

There is not much need for crate inspection these days, but…

It is probably the best beer crate inspection system in the world.