At the threshold of 2022, the past year - actually the last two years - have been incredible in more than one sense. Although the Covid19 pandemic and electronics supply chain issues continues to provide worldwide frustration, the machine vision market has grown at a steady and high pace.

Looking ahead, the pace doesn’t seem to slow down mainly because the technology adaptation of companies will accelerate this.

At JLI we have witnessed this in 2021, seen a more than average growth and hired 9 new employees. They are all helping us develop and solve around 50 running projects.

At JLI we are certain that also in 2022 the machine vision technology will enable more automation and enhance inline quality inspection, resulting in new and wider areas of applications. We want to stay ahead of the competition and have decided to hire additional engineers enabling us to dedicate more time to research and development.

Some of these extra ressources will go into further developing our own machine vision platform with new advanced tools such as automatic diagnostic, making sure that our interfaces support Industry 4.0 and PS-net. Two other main areas and probably the most prominent will be machine learning and 3D.

Machine Learning (ML)

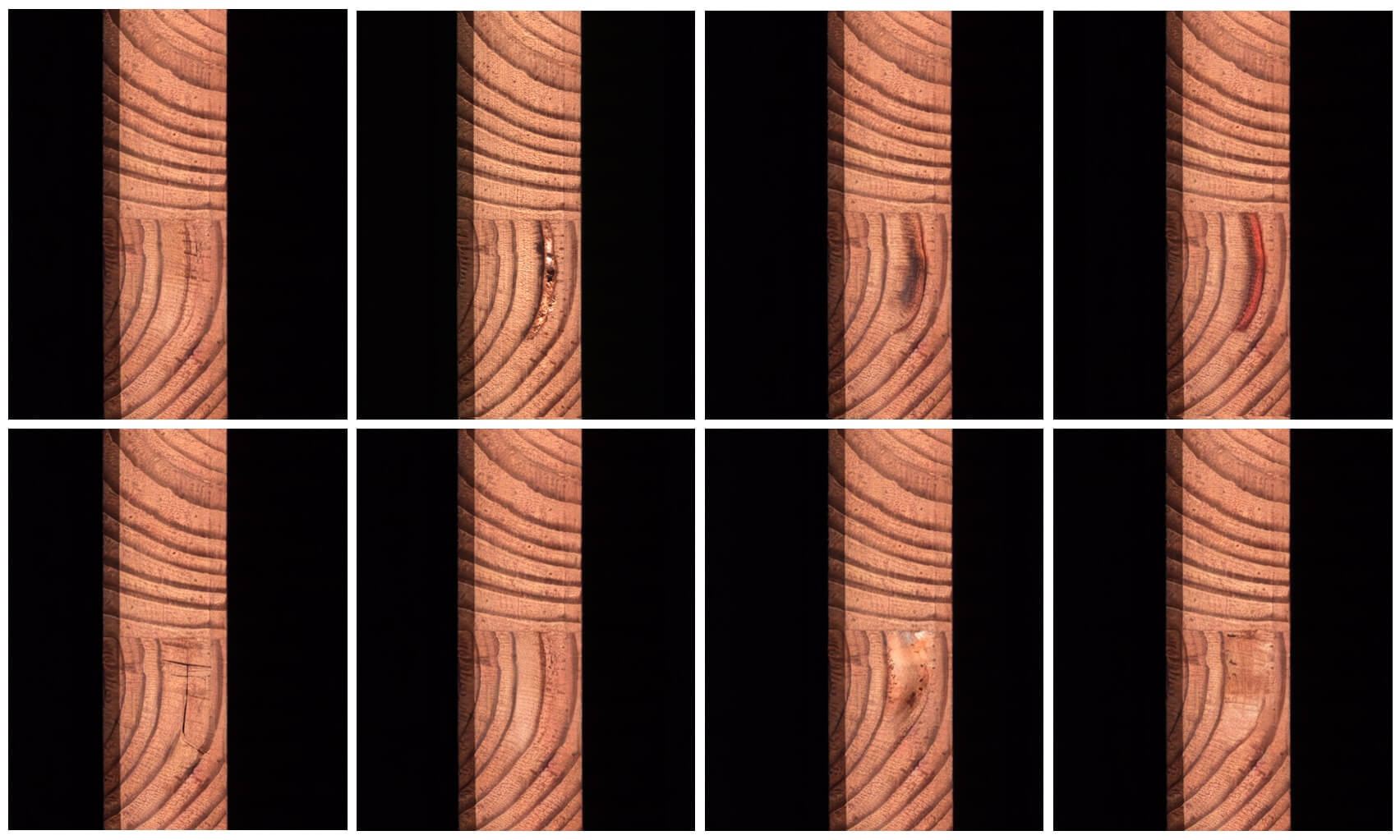

Machine learning-based models, when correctly trained, excel in detecting anomalies and classifying defects. Today, ML anomaly detection may add the possibility of detecting a defect or classifying it, but the defect still needs to be visible in the image and many integrators/customers forget that ML is just another tool that helps us locate what is already present in the images - it often needs to be combined with traditional methods.

An overlooked issue when you first set out to explore the world of ML is the robustness. There are commercially pre-trained networks available on the market, but at JLI we have found that if you want extra high detection rates, you need dedicated networks trained on the defects you are facing acquired from images taken from a setup inline in production.

It’s basically all about:

- Gathering good images.

- Cleaning, preparing and correctly annotating the images.

- Choosing the model and training it.

- Testing it on new real world images.

- Improving it and this is an iterative process that may take time before you have reached a satisfactory result.

In the years to come we expect to work on: better annotation tools, tighter integration with hardware optimizing the real time execution, model monitoring of data drift e.g. when inspecting wood that may have seasonal or supplier variations, test/validation of ML to be used in medical device applications, and generally applying ML on more data such as 3D point clouds adding extra layers of robustness.

Again in 2022 JLI will focus on raw materials such as wood, steel, plastic and glass, where we expect to further strengthen our capabilities in inspection of complicated surface structures.

3D

There’s no denying that 2D imaging has it’s limitations. Companies may in certain applications more efficiently monitor and examine their products with 3D imaging. Available technologies include stereo, laser-triangulation, time-of-flight, fringe-projection, confocal sensors etc. Each of these technologies has strengths and weaknesses depending on whether the product is moving, which raw material the product is and how accurate the depth information needs to be. In the coming years JLI expects to see a manifestation of a fragmented market and the price/performance ratio to be improved.

We also expect to further explore the possibilities of tying together color 2D and 3D information especially when it comes to surface inspection. Detecting difficult defects such as cracks, scratches, dust in paint, orange peel on curved surfaces still hasn’t really been solved, but by combining 2D and 3D we are getting closer.

Research on obtaining 3D data in the hot end of glass production is another area that JLI will focus on in 2022. Transparent glass is a very challenging raw material to measure 3D inline in production. The benefits are obviously that quality data at an early stage can help improve yield and in the future potentially create a closed loop.

Get in touch

Please bear in mind that not all machine vision applications call for implementation of the latest and new trending components/technologies. Often new components/technologies act as just another tool in the belt, that together with traditional machine vision will help solve your application.

At JLI we try to maintain a solid perspective with respect to new components/technologies that continue to enable more productive manufacturing for our customers.

If you have any questions feel free to send us an email at info@JLIvision.com.