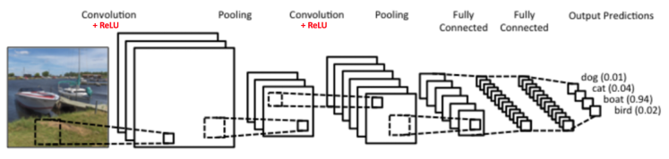

Machine learning is changing the world and that also applies for the world of machine vision. ML opens up doors for even more possibilities of solving dificult inspection tasks with machine vision.

Here is the basics you need to know on your first steps on your Deep learning journey

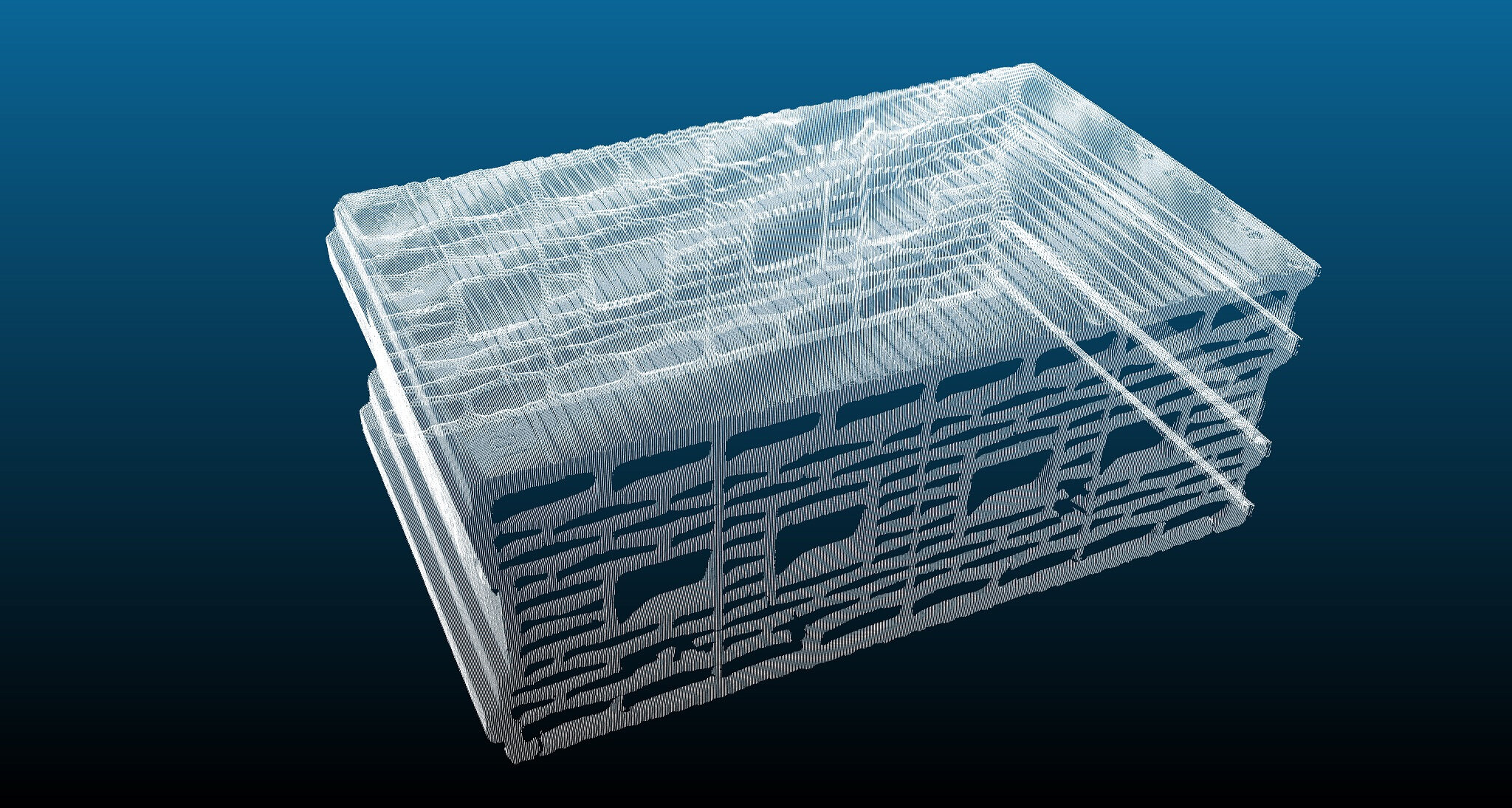

Structural applications such as measuring dimensions and depth can be performed by traditional “hand crafted” machine vision. They are easy to test and potentially expand with functionality. Aesthetic applications on the other hand consists of ensuring that the finished product fulfills the end-users or consumers expectations. Typical defects could be scratches, holes or color deviations. As opposed to structural applications it can be difficult to define objective requirement specifications. In practice good and bad samples are collected and used as reference in manual inspection. Previously aesthetic applications were often left unsolved because of the shortcomings of traditional machine vision, but by using machine learning it is in some cases possible. Supervised learning can provide solid results and is often considered the best approach, but it requires many annotated training images. Annotation is time consuming and it can be difficult to get images upfront in a machine vision application.

In the future vision companies will use both machine vision and machine learning to complement each other and use the strong sides of each technical domain. At JLI we call it “Hybrid Vision” and it is the perfect solution for "aesthetic" applications. The two domains are merging more and more, so it requires a skilled and experienced vision engineer / data scientist to know what technique to use, and when. At JLI we use “Hybrid Vision” to exploit the advantages of each technology and create custom solutions with high accuracy.

Do you want to know more about the craft of machine learning?