Ask anybody in automation or mass production about Industry 4.0 and they will tell you that it is the new holy grail – the next industrial revolution that will bring mass production to a whole new level. Then ask them to define what Industry 4.0 is, and you will notice uncertainty in their reply. Ask them then how far they have gotten with the transformation of their own company and the uncertainty will shift into… silence.

Industry 4.0 is a hard concept to grasp. While former industrial revolutions were characterized by one new production concept or technology, Industry 4.0 seems to be an umbrella covering technologies as diverse as 3D printing, drones, IoT and data analysis. How do you combine all that and how do you make it work for your company? The answer seems to be – you don’t – What you do is you pick the concepts and technologies that suit you best (like you would pick courses from a menu) and then you start implementing.

So how do you choose your main course?

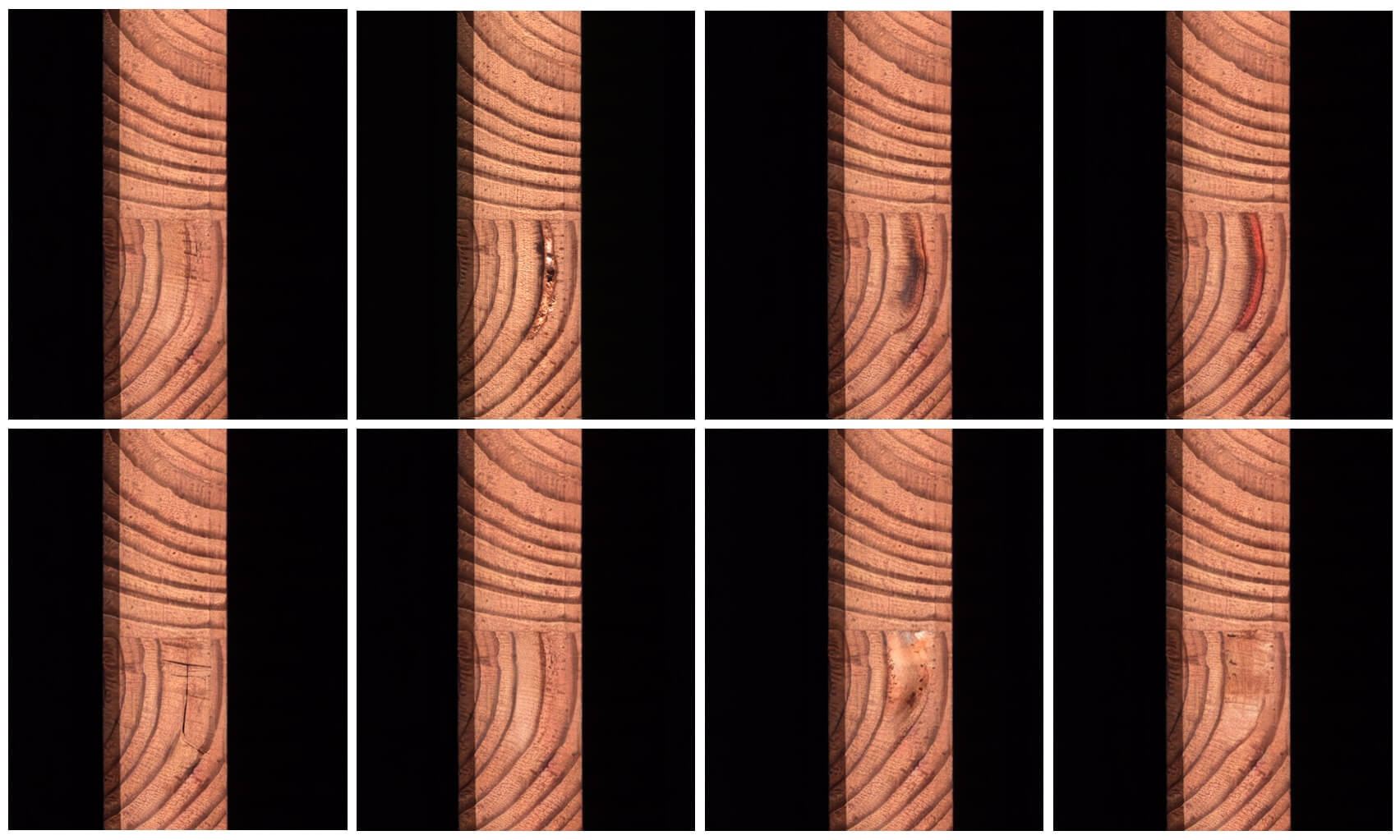

While some companies may see great benefit in some of the more exotic components of Industry 4.0 like additive manufacturing the vast majority of production companies may not. What they need is something that will help them optimize their production flows and prepare for a world of smaller and more customized production runs where automation and flexibility are essential ingredients. Industry 4.0 actually has a very promising answer to this challenge. The main concept is massive data collection and some sort of global number crunching (possibly AI) that will analyze the data and present you with trends to help optimize machine parameters and production flow…

‘But how can that be a new concept?’ One might rightfully ask. Data collection and number crunching has been used heavily for decades to optimize processes throughout industry. The new twist that Industry 4.0 brings to the table is the scale of the data collection and this has probably never been seen before: Imagine that you collect data starting from the receipt of the customer order, through sourcing of materials, through machine settings, through error codes and performance statistics, through packaging and all the way to customer feed-back. Imagine then, that you collect this for every order that you produce over time and that you have the capacity to crunch all that data to find trends not only in individual processes but across all the processes to enable global optimizations.

This clearly has some very promising perspectives and who ever gets there first will enjoy the benefits of being very hard to beat on performance.

The technology to bring us there is already in place. The vast majority of industrial processes are already equipped with electronic controllers and sensors so the data is there. Modern cloud solutions are now powerful enough to store all the data that most companies can produce and number crunching (AI) algorithms that are powerful enough are starting to emerge. What we need is ‘everything in between’ and this will be one of the main challenges for automation engineers in the coming years.

What to pick for starters?

The ‘Everything in between’ that you need to get started with Industry 4.0 is the path that data must follow from each individual sensor in the factory and all the way up to some sort of global (cloud) storage where the data analysis can take place. The traditional approach to this is to collect the data on the local machine controller, then interface the local controllers to a SCADA system and then interface the SCADA systems to a factory database that you then interface to the cloud storage. There are so many standards competing for all these interfaces that in practice you are left with no standard at all. You will simply need to custom program the local machine controllers to interface to the SCADA systems and then program them to interface to the factory database and so on… Apart from the obvious price tag, this entire exercise also leaves you with a very rigid system where every new sensor that you add will lead to reprogramming or re-configuration of the entire data path from the sensor and up to the cloud storage.

This dilemma is probably the reason why we have seen so few of these global systems in the past. Luckily Industry 4.0 has an answer to this by suggesting that we bypass all the controllers and SCADA systems by connecting the sensors more or less directly to the cloud. The standard is called OPC UA and for the first time we are here seeing a standard that all the big players in the field of industrial data collection have agreed upon. It allows each individual sensor to identify itself to the ‘cloud’ and present its data in a structured way to the systems above it – without any reprogramming.

OPC UA has the potential to wipe away all the brand-specific communication ‘standards’ that we have seen fighting during the past 20 years and this is why it should have your attention.

However, you are left with two very different challenges when going the OPC UA way: New equipment and existing equipment.

For new equipment you can start by adding OPC UA to the list of requirements and start asking what different suppliers can offer. At JLI we have already decided to follow this standard as it evolves. Currently the main (low level) standard is in place and the more high-level standards by equipment type are in the making. We will follow these standards closely and implement them in our core system as they evolve.

For existing equipment, you may be facing a much greater challenge. At a recent Industry 4.0 seminar here in Denmark a multi-national company complained that they were the result of a merger of close to 100 production units and as a result thereof they now had every possible brand of sensor, PLC and SCADA system represented in their factories. Interfacing all that to a central cloud system is a gigantic task and they hardly knew where to begin. Retrofitting a full Industry 4.0 data solution is hardly always the way to go, but that does not mean you should not try. You do not need every sensor in your factory to be connected before you can enjoy the benefits of optimization. In fact, you can start learning and optimizing as soon as the first sensor is on-line. And there is no harm in asking the suppliers of your existing equipment if they can help. At JLI we never give up on a system and that means we are still capable of adding new functionality to 15-year-old systems – we do that frequently. This means that the OPC UA functionality that we add to our new systems can often be retrofitted to the old systems as well.

And desert…

Industry 4.0 is not going away. It is here to stay, and like the 3 former revolutions it will become part of our DNA over time. Whenever we find it hard to grasp and overwhelming, we should perhaps remember that the 3 former revolutions did not revolutionize everything at once. They started with one steam engine and one robot and with the help of a few hard-working revolutionaries they evolved from there.

Maybe we are the next revolutionaries?