If you are considering investing in machine vision, it will most likely be due to at least one of these reasons:

- You want to improve your quality control to catch more defects and discard fewer good items.

- You want to automate manual processes to use your resources more efficiently.

You can achieve both with a machine vision project, but since implementing a machine vision solution isn't free, it is always a good idea to calculate if it makes sense to go through with the investment.

Remember the intangible improvements

Below we will go through the parameters of an ROI calculation so you will know what to consider for your project.

First, however, there is an important note to this kind of ROI calculation. You can create value in two ways: either by optimizing resources put into the production process or by improving quality.

With an ROI calculation, it will always be easiest to consider the things you save - it is easier to quantify. It is more difficult to determine the value of better quality, which will bring you happier customers who recommend the product to their network, so that they become customers, etc.

Nevertheless, that intangible value is crucial to consider when concluding whether a machine vision project is worth the investment or not.

But let's look at how you can make a solid ROI calculation for your machine vision project.

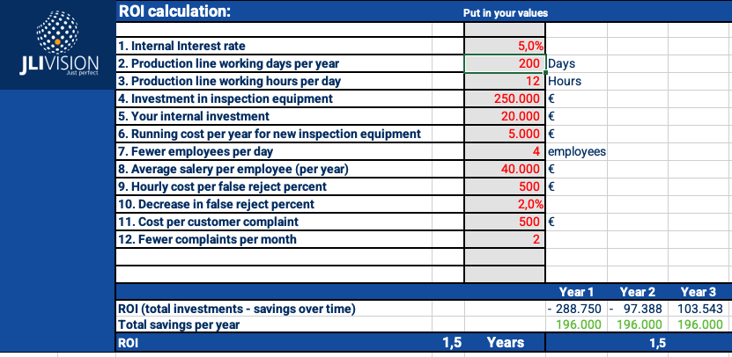

In the following, we go through the specific parameter in the calculation, and to help you make your own, we have created a calculator you can use.

You can download it here.

The numbers in () refer to the lines in the ROI calculator.

The investment

If we look at the investment first, there are several elements you need to take into account.

The actual investment in equipment for inspection (4) is, of course, the most important. This consist of both the vision solution and the other equipment you need to automate the manual process. If you need internal resources to develop and implement the system, you should also consider these.

In addition, there are some ongoing costs for operation and maintenance (6). They are typically quite low once the system is up and running, but they should still be included in the calculation.

If the solution needs to be financed, you must also consider the loan's interest rate (1).

Optimizations of production costs

If we turn our attention to the optimizations on the production line, you should include the following:

- Working days per year for the production line. (2)

- Working hours per day for the production line. (3)

- Average salary per employee on the production line. (8)

- The number of employees you will be able to save per day by automating inspection. (7)

So, if you today have 16 people performing quality control on the production line per day, and you will be able to reduce that to 2, you should put 14 in the ROI calculator.

Improvements in quality

The next step is to look at how much you can optimize production by improving quality control.

An important number is how many percentage points you can lower the percentage of false rejects. If you currently have a false reject percentage of 3%, which you can reduce to 0.5%, then you have a "Decrease in false reject percent" of 2.5.

The next step is determining how much one percent of false rejects cost per hour = “Hourly cost per false reject percent ".

Example:

If you produce 180 items in an hour and have a false reject of 3%, that will give you 5.4 false rejects per hour. If each false reject costs 100 €, then 3% costs 540 € per hour - and 1% costs 180 €. In this case, your "Hourly cost per false reject percent" is 180 €.

Discarding fewer good items is one way to optimize. The other is to reduce the number of bad items that slip through and potentially end up with a complaint from a customer.

Therefore, you must consider what it approximately costs to handle a customer complaint - including everything from administration to shipping - and how many fewer customer complaints you can expect to receive every month.

Here you can see an example of an ROI calculation on a machine vision project:

Go for an ROI of fewer than 3 years

You might not have solid data on all the above-mentioned parameters, which is okay. You can still use your best guess as a starting point. The ROI calculation will rarely be 100% accurate, but it can still help you get an overall indication of whether a machine vision solution is worth the investment.

But when do you have a good ROI then? It depends on your specific situation, but in general, we see that companies aim for a positive ROI of fewer than 3 years on these types of projects.