Imagine you have two tablets next to each other. Both the same size, and the same white color. Seemingly the same.

With the human eye or a regular camera, you can't tell them apart, but in reality, the chemical composition is different.

You could easily imagine a quality control task of differentiating between materials that on the surface look the same, and while it may sound like an impossible task to solve with a vision system, it's not.

The solution is hyperspectral imaging, which is gaining ground as the technology matures. There are several suppliers that can deliver hyperspectral cameras, and one of them is Danish Qtechnology, with whom we collaborate.

Let's take a closer look at how hyperspectral imaging works and how it can be used in practice.

Capturing both visible and infrared wavelengths

Light is electromagnetic waves and hyperspectral imaging captures and processes information from across the electromagnetic spectrum.

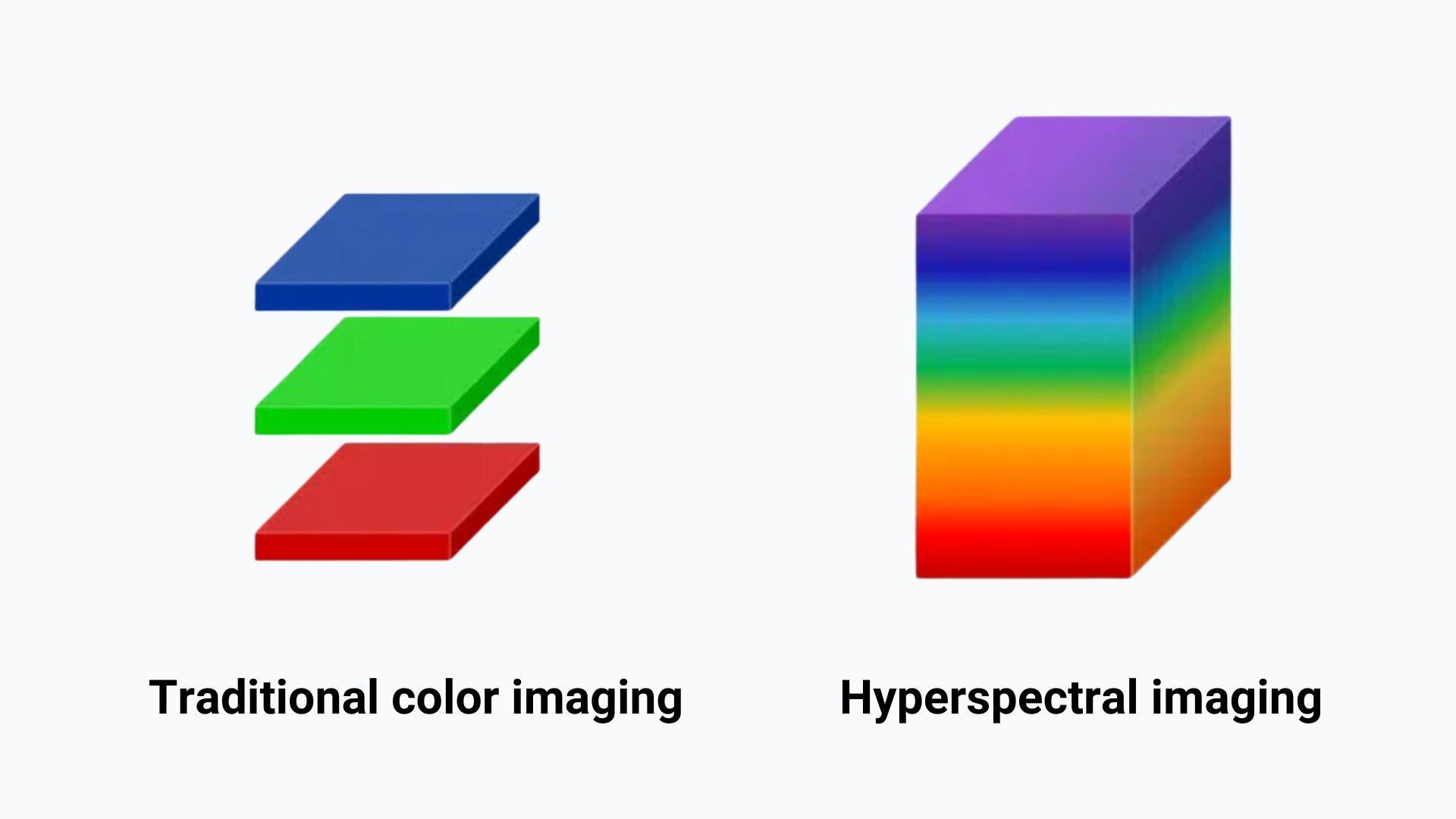

Unlike traditional color imaging, which records light in just three color bands (red, green, and blue), hyperspectral imaging divides light into many more spectral bands (up to 900 bands to be exact, if we’re talking about Qtechnolgy’s cameras), ranging from the visible to the short-wave infrared (430-1700 nm).

This enables the detection of subtle differences in the chemical composition, material properties, and biological characteristics of objects.

This enables the detection of subtle differences in the chemical composition, material properties, and biological characteristics of objects.

The process basically looks like this:

- An object is illuminated, and the hyperspectral camera captures the reflected light from the object.

- The light is then dispersed into a continuous spectrum of wavelengths using a diffraction grating. Qtechnology's hyperspectral camera employs a reflective diffraction grating with a nanostructured pattern, that enables high diffraction efficiency across a broad wavelength range, from the visible to the short-wave infrared.

- Each pixel in the image now contains a full spectrum of light rather than a single intensity value.

- Advanced algorithms process this data, analyzing the spectrum of each pixel to detect variations, which helps in identifying specific materials or features.

Use cases for hyperspectral imaging in quality control

One of the most widely known use cases for hyperspectral imaging is within agriculture, as the technology can help detect disease, nutrient levels, etc. in plants.

However, there is also a wide range of use cases in industrial quality control.

For example, we have used hyperspectral imaging to detect water droplets on the surface of steel tools that have gone through an autoclave process for sterilization. To make sure there are no small water droplets left on the surface, hyperspectral imaging can be used to detect the otherwise invisible water droplets because they absorb different electromagnetic wavelengths than the steel. Even when the tool is packed in a bag, it is actually possible to detect water on the surface of the steel.

.jpg?width=720&height=405&name=water%20on%20steel%202%20(1).jpg) Hyperspectral imaging will be useful for e.g. sorting plastic into specific plastic types. Although the plastics may look the same visually, their chemical composition - their polymer basis, filler and other additives like flame retardants, softeners etc. - is different and this can be detected with a hyperspectral camera.

Hyperspectral imaging will be useful for e.g. sorting plastic into specific plastic types. Although the plastics may look the same visually, their chemical composition - their polymer basis, filler and other additives like flame retardants, softeners etc. - is different and this can be detected with a hyperspectral camera.

As mentioned in the introduction, hyperspectral imaging can also be used for quality control in the pharmaceutical industry - anything from detecting if the chemical composition of a medicine differs from the desired one to measuring the thickness of a pill's coating.

In general, hyperspectral imaging could be applied in many quality control scenarios where you need to differentiate between materials that visually look the same but are in fact different.

%20Stor.jpeg)