Investing in a machine vision system is a significant step towards enhancing the quality control processes in industrial manufacturing.

However, to ensure that this investment stands the test of time, it is imperative to embed robustness into every aspect of the solution. In this blog post, we delve into the intricacies of creating a technically robust machine vision solution, focusing on hardware, software, and processes.

Building Durability with Hardware

The foundation of a resilient machine vision system lies in its hardware. The durability and performance of the system are directly influenced by the quality and compatibility of its components.

Component Selection: The journey to a durable system begins with the careful selection of components. Opt for burn-in-tested computers to ensure that they can endure prolonged usage without faltering.

Future-Proofing: While predicting the future product priorities of hardware manufacturers is challenging, choose hardware with a higher likelihood of spare parts availability in the next 5 to 10 years.

Lighting Considerations: Lighting plays a pivotal role in machine vision. Design your solution with ample lighting, ensuring that even at 50% capacity, the light sources provide the required illumination. This foresight accommodates the inevitable decrease in light output over time.

Consider Calibration and Alerts

A robust machine vision system is not just about strong hardware; it also requires intelligent design to accommodate and adapt to changes over time.

Proactive Design: Integrate calibration capabilities into your solution to continuously adjust the lighting, ensuring it meets the inspection task requirements despite output losses.

Alert Systems: Implement alert mechanisms to notify you of potential issues, such as computer overload or light drift, enabling timely interventions and preventing system failures.

Software Robustness

The software layer of a machine vision system is its brain, interpreting data and making critical decisions. Ensuring its robustness is paramount for reliable operation.

Fail-Safe Mechanisms: Ensure that your software is fail-safe. Employ monitoring programs to oversee the performance of other software components, restarting them if performance dips to maintain optimal functionality.

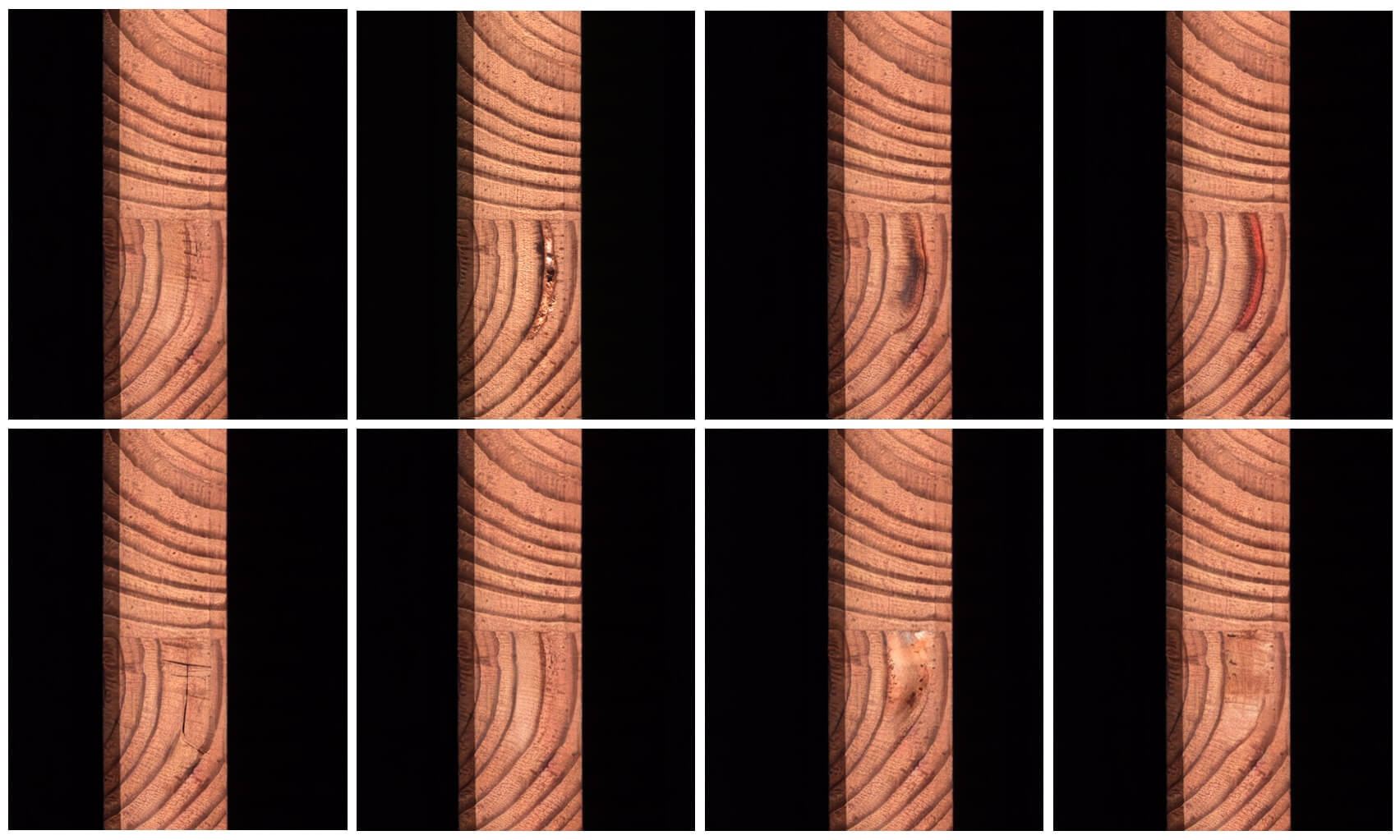

Redundant Methods: Employ redundant inspection methods and gather extensive data to identify and eliminate outliers, enhancing the system’s resilience against external disturbances like dust and vibrations.

Emphasizing Maintenance and Documentation

The longevity of a machine vision system is significantly influenced by the ease and effectiveness of its maintenance practices, as well as the availability of thorough documentation.

Remote Maintenance: Design your system to allow for remote maintenance, ensuring that any issues can be addressed promptly, regardless of physical location.

Thorough Documentation: Maintain comprehensive technical documentation of the solution. This practice is crucial for facilitating effective service and maintenance activities, expanding the lifetime of the system.

Design your machine vision system with a holistic approach

Creating a future-proof machine vision solution requires a holistic approach, addressing hardware durability, software robustness, and comprehensive maintenance practices.

By following the guidelines outlined in this post, engineers can ensure that their machine vision systems remain reliable, efficient, and relevant, even as the years roll by and technology continues to evolve.