.jpg?width=1920&name=3%20real-life%20examples%20(1).jpg) Artificial intelligence is on the agenda in many companies that want to optimize and automate different parts of their operations.

Artificial intelligence is on the agenda in many companies that want to optimize and automate different parts of their operations.

This also applies to quality control with machine vision, and with good reason. With AI - or rather machine learning which is a subset of AI - we have a tool that can both take over specific manual tasks within inspection to free up resources and even succeed with inspection tasks that humans struggle with.

At JLI, we use machine learning in our solutions when it makes sense. And when is that? Often it is a matter of having to inspect an organic material for errors that the trained eye can see and evaluate from experience but are difficult to describe accurately enough for a classical algorithm to work. Often because there are several factors at play at the same time.

Let’s bring it down to earth with some examples.

AI in steel inspection

20 years ago, we at JLI vision made a solution for inspecting railway tracks. However, we had to settle for a solution that took images and saved them as documentation for subsequent manual inspection, as it was too complex to automate the inspection itself. It was not a question of color differences, size, or particular errors that you could create an algorithm for.

There was a challenge with reflections in the material, drops from cooling water could disturb the image, there could be nicks in the rails or slag scale . All in all, it required an experienced inspector to assess all these factors simultaneously to determine if there was a severe defect in the rail.

But that was then. Because with machine learning, we can now let a neural network train on a large number of images of rails, which are annotated with relevant types of faults, until it becomes as effective at identifying the faults as the experienced inspector.

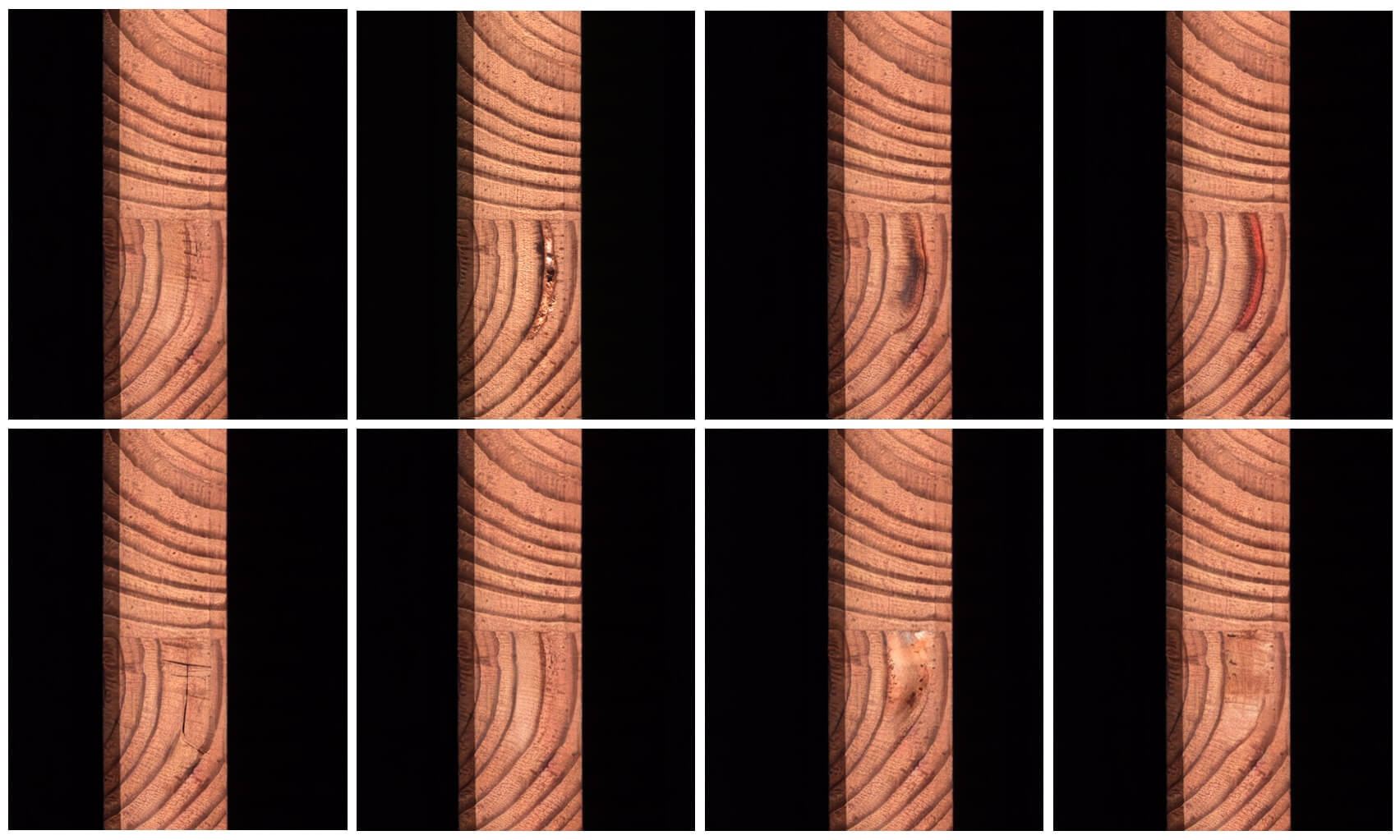

AI in wood inspection

In wood inspection, we find another example. We have helped one of our customers inspect lacquered wooden boards, where we look for defects in the lacquer. There are several different types of defects - flaws in the paintwork, notches, dust in the paintwork, etc. - that you want to classify because they are indications of specific production errors that need to be corrected.

But how do you write an algorithm that can determine if the dust in the paint comes from the production process, which makes it an error that needs to be corrected, or if it is simply dust that has settled after the board has been lacquered?

But since this is something the experienced eye can assess, so can an AI network if we train it on enough samples.

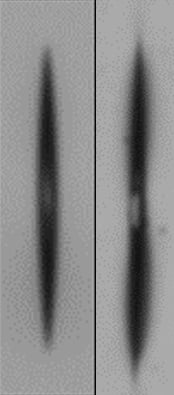

AI in glass inspection

A third example comes from the glass industry. Here we have helped a customer detect defects in glass tubes, specifically if the tubes had so-called airlines. However, the presence of airlines was not enough in itself; it was a question of whether or not the airline was so close to the surface that there was a risk of open airlines. If so, we were looking at a potential critical defect.

A third example comes from the glass industry. Here we have helped a customer detect defects in glass tubes, specifically if the tubes had so-called airlines. However, the presence of airlines was not enough in itself; it was a question of whether or not the airline was so close to the surface that there was a risk of open airlines. If so, we were looking at a potential critical defect.

This was an example of a very tricky defect for the human eye to assess, but we have been able to train an AI network to tell the difference and determine whether the overhead lines are critical defects.

So AI or machine learning can improve your quality inspection both when you want to streamline manual inspection and when it is too challenging for the human eye to actually make the assessment.