Machine learning is often perceived as a uniform technology. However, it's a diverse field with various models and techniques, each uniquely suited for specific tasks. In industrial quality control, leveraging the right machine learning technique is important to achieve your goals.

In this blog post, we will dive into three key machine learning techniques - classification, instance segmentation, and anomaly detection - and when to use them.

Classification: Precision in Categorization

Classification involves categorizing data into predefined classes based on distinct features or attributes. In a production line, for instance, a computer vision system equipped with classification algorithms can inspect and sort products according to their visual characteristics.

Consider a production line where various items are checked for surface defects like scratches or cracks. Here, the computer vision system, trained on a dataset comprising images of both flawless and defective items, learns to discern visual features that differentiate a good item from a defective one. Once operational, it can evaluate new product images, classifying them as either acceptable or defective. This real-time defect detection outperforms manual inspection methods in both speed and precision.

Instance Segmentation: Detailed Analysis

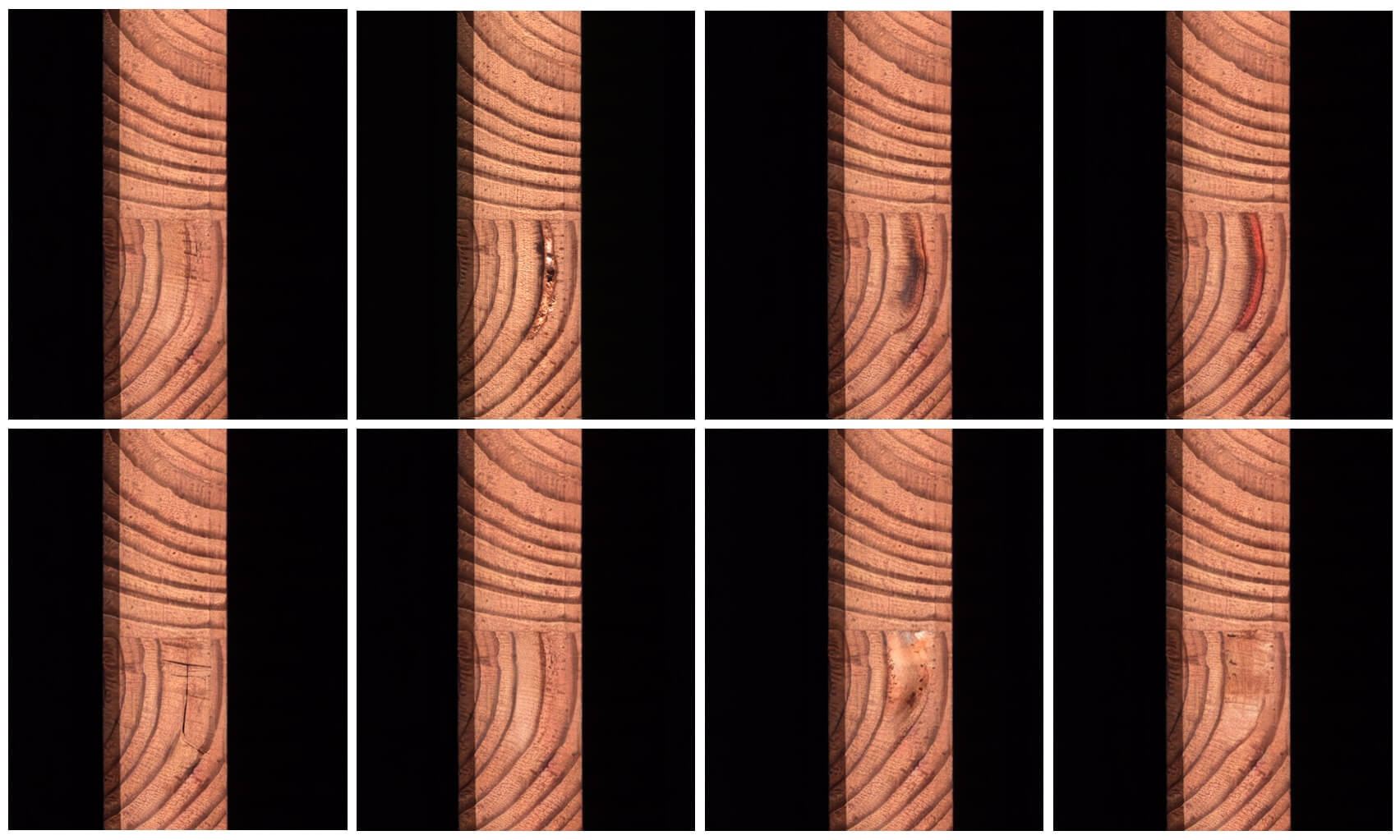

Instance segmentation takes image analysis a notch higher than traditional segmentation. It involves assigning labels to pixels in an image to identify and differentiate individual objects. In quality control, instance segmentation can pinpoint and assess specific product defects.

While classification detects and labels defects, instance segmentation provides detailed information about the defect’s size and shape, aligning with production tolerances. For example, in surface inspection, instance segmentation could measure the extent of a scratch or a dent, offering precise data to inform quality decisions.

Anomaly Detection: Unsupervised Learning for Unforeseen Defects

Diverging from the supervised learning approach of classification and instance segmentation, anomaly detection falls under unsupervised learning. It doesn’t rely on annotated images for training. Instead, the network is fed with images of 'normal' or defect-free items, establishing a baseline for comparison.

In practice, anomaly detection is invaluable for spotting defects that deviate from the norm but might not be explicitly defined. For example, in the production of automotive parts, anomaly detection can identify subtle, non-conformant features that might escape human inspectors or a standard vision system.

This can significantly improve the efficiency and accuracy of industrial quality control, as it can detect defects that may not be easily detected by human inspectors or other traditional quality control techniques.